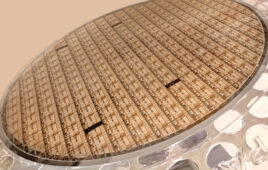

Enthone Inc. announces the construction of a new production facility for the exclusive manufacturing of certain components of the company’s next generation ViaForm copper damascene electroplating chemistries. Scheduled to open this fall, the facility is being built to meet a more stringent set of requirements for the semiconductor wafer fabrication market.

Enthone Inc. announces the construction of a new production facility for the exclusive manufacturing of certain components of the company’s next generation ViaForm copper damascene electroplating chemistries. Scheduled to open this fall, the facility is being built to meet a more stringent set of requirements for the semiconductor wafer fabrication market.

The Enthone ViaForm Copper Damascene Manufacturing Facility further expands the company’s high volume manufacturing production and advance research center, all of which are located at its global headquarters in West Haven, Conn. Similar to the HVM, the new facility will exceed Class 1,000 packaging requirements and feature computer integrated manufacturing, including in-line particle count, fully automated and enclosed chemical distribution, and dedicated processing streams. Supported by the company’s Customer Value Six Sigma program, all copper damascene chemical manufacturing adheres to stringent batch-to-batch control and consistency standards as required by semiconductor producers worldwide.

Jason Maupin, Vice President – Enthone Americas, says “This expanded manufacturing capacity tangibly demonstrates Enthone’s commitment to addressing our customers exacting manufacturing requirements, as we continue to develop electrochemistries to meet advanced copper interconnects at 20 nanometers and beyond.”

Enthone Inc., an Alent plc company, is a supplier of specialty chemicals and coatings to the automotive, building hardware, energy, aerospace, jewelry, industrial finishes, printed circuit board, and semiconductor industries.

Release Date: May 27, 2014

Source: Enthone Inc.