The same slip-and-stick mechanism that leads to earthquakes is at work on the molecular level in nanoscale materials, where it determines the shear plasticity of the materials, according to scientists at Rice University and the State University of Campinas, Brazil.

The same slip-and-stick mechanism that leads to earthquakes is at work on the molecular level in nanoscale materials, where it determines the shear plasticity of the materials, according to scientists at Rice University and the State University of Campinas, Brazil.

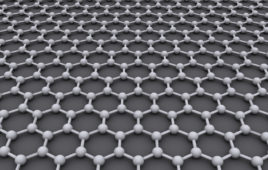

The Rice lab of materials scientist Pulickel Ajayan found that random molecules scattered within layers of otherwise pristine graphene affect how the layers interact with each other under strain.

Plasticity is the ability of a material to permanently deform when strained. The Rice researchers, thinking about future things like flexible electronics, decided to see how graphene oxide “paper” would handle shear strain, in which the sheets are pulled by the ends.

Such deep knowledge is important when making novel advanced materials, says Chandra Sekhar Tiwary, a lead author of the new paper in the American Chemical Society journal Nano Letters and a Rice postdoctoral research associate.

“We want to build three-dimensional structures from two-dimensional materials, so this kind of study is useful,” he says. “These structures could be a thermal substrate for electronic devices, they could be filters, they could be sensors or they could be biomedical devices. But if we’re going to use a material, we need to understand how it behaves.”

The graphene oxide paper they tested was a stack of sheets that lay atop each other like pancakes. Oxygen molecules “functionalized” the surfaces, adding roughness to the otherwise atom-thick sheets.

In experiments and computer models, the team found that with gentle, slow stress, the oxides would indeed catch, causing the paper to take on a corrugated form where layers pulled apart. But a higher strain rate makes the material brittle. “The simulation performed by our collaborators in Brazil provides insight and confirms that if you pull it very fast, the layers don’t interact, and only one layer comes out,” Tiwary says.

“After this study, we now know there are some functional groups that are useful and some that are not. With this understanding we can choose the functional groups to make better structures at the molecular level.”

Rice graduate student Soumya Vinod is a lead author of the paper. Co-authors are Rice graduate student Sehmus Ozden and undergraduates Juny Cho and Preston Shaw; postdoctoral researcher Leonardo Machado and Professor Douglas Galvão of the State University of Campinas, Brazil; and Robert Vajtai, a senior faculty fellow in materials science and nanoengineering at Rice. Ajayan is chair of Rice’s Department of Materials Science and NanoEngineering, the Benjamin M. and Mary Greenwood Anderson Professor in Engineering, and a professor of chemistry.

The Department of Defense and Air Force Office of Scientific Research supported the research.

Release Date: January 19, 2016

Source: Rice University