When it comes to the growth of graphene — an ultrathin, ultrastrong, all-carbon material — it is survival of the fittest, according to researchers at The University of Texas at Austin.

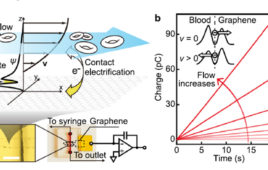

The team used surface oxygen to grow centimeter-size single graphene crystals on copper. The crystals were about 10,000 times as large as the largest crystals from only four years ago. Very large single crystals have exceptional electrical properties.

“The game we play is that we want nucleation (the growth of tiny ‘crystal seeds’) to occur, but we also want to harness and control how many of these tiny nuclei there are, and which will grow larger,” says Rodney S. Ruoff, professor in the Cockrell School of Engineering. “Oxygen at the right surface concentration means only a few nuclei grow, and winners can grow into very large crystals.”

The team — led by postdoctoral fellow Yufeng Hao and Ruoff of the Department of Mechanical Engineering and the Materials Science and Engineering Program, along with Luigi Colombo, a material scientist with Texas Instruments — worked for three years on the graphene growth method. The team’s paper, “The Role of Surface Oxygen in the Growth of Large Single-Crystal Graphene on Copper,” is featured on the cover of the Nov. 8, 2013, issue of Science.

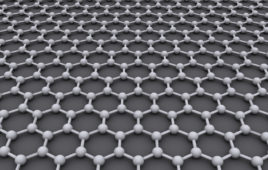

One of the world’s strongest materials, graphene is flexible and has high electrical and thermal conductivity that makes it a promising material for flexible electronics, solar cells, batteries and high-speed transistors. The team’s understanding of how graphene growth is influenced by differing amounts of surface oxygen is a major step toward improved high-quality graphene films at industrial scale.

The team’s method “is a fundamental breakthrough, which will lead to growth of high-quality and large area graphene film,” says Sanjay Banerjee, who heads the Cockrell School’s South West Academy of Nanoelectronics (SWAN). “By increasing the single-crystal domain sizes, the electronic transport properties will be dramatically improved and lead to new applications in flexible electronics.”

Graphene has always been grown in a polycrystalline form, that is, it is composed of many crystals that are joined together with irregular chemical bonding at the boundaries between crystals (“grain boundaries”), something like a patch-work quilt. Large single-crystal graphene is of great interest because the grain boundaries in polycrystalline material have defects, and eliminating such defects makes for a better material.

By controlling the concentration of surface oxygen, the researchers could increase the crystal size from a millimeter to a centimeter. Rather than hexagon-shaped and smaller crystals, the addition of the right amount of surface oxygen produced much larger single crystals with multibranched edges, similar to a snowflake.

“In the long run it might be possible to achieve meter-length single crystals,” Ruoff says. “This has been possible with other materials, such as silicon and quartz. Even a centimeter crystal size — if the grain boundaries are not too defective — is extremely significant.”

“We can start to think of this material’s potential use in airplanes and in other structural applications — if it proves to be exceptionally strong at length scales like parts of an airplane wing, and so on,” he says.

Another major finding by the team was that the “carrier mobility” of electrons (how fast the electrons move) in graphene films grown in the presence of surface oxygen is exceptionally high. This is important because the speed at which the charge carriers move is important for many electronic devices — the higher the speed, the faster the device can perform.

Yufeng Hao says he thinks the knowledge gained in this study could prove useful to industry.

“The high quality of the graphene grown by our method will likely be developed further by industry, and that will eventually allow devices to be faster and more efficient,” Hao says.

Single-crystal films can also be used for the evaluation and development of new types of devices that call for a larger scale than could be achieved before, added Colombo.

“At this time, there are no other reported techniques that can provide high quality transferrable films,” Colombo says. “The material we were able to grow will be much more uniform in its properties than a polycrystalline film.”

This study was funded at UT Austin by the W.M. Keck Foundation, the Office of Naval Research, and the Southwest Area Nanotechnology Center, which is supported by the Nanoelectronics Research Initiative. The paper’s co-authors are from the Cockrell School of Engineering and the Department of Physics. Other co-authors are from Columbia University, A*STAR (in Singapore), Sandia National Laboratories-Livermore, Rice University, and Texas Instruments.

Release Date: November 14, 2013

Source: UT Austin