Graphene is a two-dimensional material, very thin, composed of a single layer of carbon atoms, but also flexible like plastic and with a mechanical resistance a hundred times higher than steel. This is why it is considered practically perfect for multiple uses in industrial and technological fields; however, it is difficult to produce, making its use extremely expensive.

A study, conducted in Trieste (Italy) by the Istituto officina dei materiali of the Italian National Research Council (Iom-Cnr) and by the Department of physics of the University of Trieste, just published in the prestigious Science magazine, identifies the mechanism of graphene growth on the surface of a common metal, nickel, opening up new possibilities in production technologies.

“We know that individual atoms are always present on metal surfaces, where they can freely move around and participate in many of the processes that take place there,” explains Cristina Africh, of Iom-Cnr. “In our study we have shown that, on a nickel surface, the mobile metal atoms act as catalysts, facilitating the formation of graphene.”

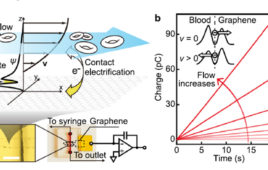

The scientific team was able to record this process in real time, revealing the behavior of individual surface atoms, by means of a high-speed scanning module developed in the recent years in collaboration with Elettra-Sincrotrone Trieste and recently improved thanks to European funding.

“With a scanning tunneling microscope,” continues Laerte Patera, who worked on this project at Iom-Cnr for his PhD thesis in nanotechnology at the University of Trieste, “we filmed what happens at the edge of the graphene sheet during its growth, at a temperature of about 450 degrees Celsius, collecting up to 60 images per second, a frame rate much higher than those used in cinematography or in television and perceived by the human eye.”

“From the videos it is clear that the growth process takes place line by line, like a knitting machine weaving a thread to form a piece of cloth: at the microscopic level, the individual nickel atoms perform the same function as the machine needle, adding new stitches to the edge of the fabric in an ordered sequence,” explains Giovanni Comelli, from the University of Trieste. “Numerical simulations, conducted at our University under the guidance of Maria Peressi and performed in collaboration with the Universidad Nacional de Córdoba (Argentina), mostly based on quantum mechanics, clarify all details of the experimental results and clearly explain the role played by nickel adatoms which, by temporarily attaching themselves at the graphene edges, allow the inclusion of new carbon atoms.”

“In addition to its relevant scientific value, this result is of considerable interest for applications, since one of the most widely used methods currently employed for industrial production of graphene makes use of a nickel substrate to grow graphene layers characterized by few defects at a reduced production cost,” concludes Africh. “Understanding the details of the growth mechanism, so far unknown, is therefore fundamental to define a strategy for the development of new and more efficient graphene production processes at the industrial level.”