Griffith University researchers are creating tiny high-tech chips that will detect problems in ageing gas and oil pipelines, preventing potential catastrophic events.

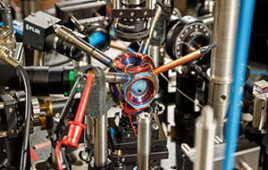

A team from Griffith’s Queensland Micro- and Nanotechnology Centre is developing the novel, low-cost and highly sensitive compact sensors that will detect and monitor changes in harsh environments, such as strain, pressure, flow rate, magnetic field and temperature.

With safety in the resource sector a globally critical issue, the researchers said an affordable, robust, and real-time monitoring system was imperative – and they have already made recent important discoveries furthering this work within the center.

Dr. Dzung Dao, Professor Nam-Trung Nguyen, Professor Sima Dimitrijev, and Alan Iacopi will use a $403,000 Australian Research Council Linkage Project grant for their project “Superior Silicon Carbide Nanoscale Sensors (SCANS) for Harsh Environments.”

Conducted in partnership with SPT Microtechnologies, the team will develop silicon-carbide (SiC) nanoscale sensors (SCANS) that will be commercialized to improve the safety and efficiency of systems that operate under hostile conditions.

Dao says the project would address shortcomings of current diagnostic techniques, significantly improving the reliability, safety, productivity, and efficiency of resource exploration and transportation systems in Australia.

“The resource sector, including mining, oil and gas, and geothermal industries, is one of the driving forces of the Australian economy, with the oil and gas extraction industry alone reaping approximately $50 billion for the Australian economy,” he says.

“However, our oil and gas delivery infrastructure is rapidly ageing. Internal corrosion and mechanical strain can cause the leakage in gas and oil pipelines, leading to catastrophic failures, death, injury, and environmental impacts.

“Numerous sensor technologies have been used for monitoring and accident-prevention purposes but most of the sensors are bulky or based on material like silicon, which is not suitable for long time operation in high temperature environments found in pipelines, geothermal, and mining applications.”

Researchers have discovered numerous transducer effects in single crystal silicon-carbide thin films, including the pseudo-Hall, Hall, piezoresistive and thermoresistive effects, for superior pressure, vibration, flow rate, strain and magnetic sensors. The team has published 26 high-impact journal papers in this area since 2014, and already attracted 165 citations.

Compared to silicon, silicon-carbide possesses superior mechanical strength, chemical inertness, thermal durability, and electrical stability. Silicon carbide has been widely used in the power electronics industry, which is projected to have a global market value of $1.8 billion in 2018.

Source: Griffith University