Haotian Wang, who will join the Rice faculty later this year, is the lead author of a study to transform carbon dioxide into carbon monoxide and other industrial fuels. Image: Jon Chase/Harvard Staff Photographer

Rather than allow power plants and industry to toss carbon dioxide into the atmosphere, incoming Rice University assistant professor Haotian Wang has a plan to convert the greenhouse gas into useful products in a green way.

Wang, who will join Rice as the William Marsh Rice Trustee Chair and assistant professor of chemical and biomolecular engineering at the end of this year, and his colleagues have made small reactors that allow single atoms of nickel to catalyze industrial greenhouse gases into carbon monoxide, an industrial feedstock.

Currently a fellow at the Rowland Institute at Harvard, Wang and his team improved their system to use renewable electricity to reduce carbon dioxide into carbon monoxide, a key reactantin a number of industrial processes. The system is described in a paper in Joule, a Cell Press journal.

“The most promising idea may be to connect these devices with coal-fired power plants or other industry that produces a lot of carbon dioxide,” Wang says.

“About 20 percent of those gases are carbon dioxide, so if you can pump them into this cell … and combine it with clean electricity, then we can potentially produce useful chemicals out of these wastes in a sustainable way, and even close part of that carbon dioxide cycle.”

The new system, Wang says, represents a dramatic step forward from the one he and colleagues first described in a 2017 paper in Chem.

That system was barely the size of a cellphone and relied on two electrolyte-filled chambers, each of which held an electrode. The new system is cheaper and relies on high concentrations of carbon dioxide gas and water vapor to operate more efficiently — just one 10-by-10-centimeter cell, Wang says, can produce as much as four liters of carbon monoxide per hour.

The new system, Wang says, addresses the two main challenges — cost and scalability — that were seen as limiting the initial approach.

“In that earlier work, we had discovered the single nickel-atom catalysts which are very selective for reducing carbon dioxide to carbon monoxide … but one of the challenges we faced was that the materials were expensive to synthesize,” Wang says.

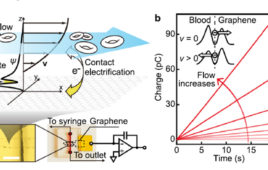

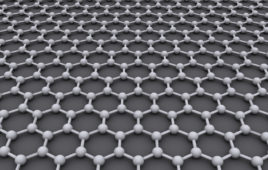

“The support we were using to anchor single nickel atoms was based on graphene, which made it very difficult to scale up if you wanted to produce it at gram or even kilogram scale for practical use in the future.”

To address that problem, he says, his team turned to a commercial product that’s thousands of times cheaper than graphene as an alternative support — carbon black.

Using a process similar to electrostatic attraction, Wang and colleagues are able to absorb single nickel atoms (positively charged) into defects (negatively charged) in carbon black nanoparticles, with the resulting material being both low-cost and highly selective for carbon dioxide reduction.

“Right now, the best we can produce is grams, but previously we could only produce milligrams per batch,” Wang says.

“But this is only limited by the synthesis equipment we have; if you had a larger tank, you could make kilograms or even tons of this catalyst.”

Going forward, Wang says, the system still has challenges to overcome, particularly related to stability.

“If you want to use this to make an economic or environmental impact, it needs to have a continuous operation of thousands of hours,” he says.

“Right now, we can do this for tens of hours, so there’s still a big gap, but I believe those problems can be addressed with more detailed analysis of both the carbon dioxide reduction catalyst and the water oxidation catalyst.”

Ultimately, Wang says, the day may come when industry will be able to capture the carbon dioxide that is now released into the atmosphere and transform it into useful products.

“Carbon monoxide is not a particularly high-value chemical product,” Wang says.

“To explore more possibilities, my group has also developed several copper-based catalysts that can further reduce carbon dioxide into products that are much more valuable.”

Source: Rice University