For more than a decade, scientists have

tried to improve lithium-based batteries by replacing the graphite in one

terminal with silicon, which can store 10 times more charge. But after just a

few charge/discharge cycles, the silicon structure would crack and crumble,

rendering the battery useless.

Now a team led by materials scientist Yi

Cui of Stanford University and SLAC National Accelerator

Laboratory has found a solution: a cleverly designed double-walled

nanostructure that lasts more than 6,000 cycles, far more than needed by

electric vehicles or mobile electronics.

“This is a very exciting development toward

our goal of creating smaller, lighter and longer-lasting batteries than are

available today,” Cui said. The results were published in Nature Nanotechnology.

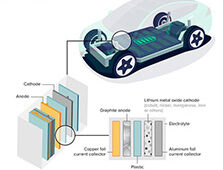

Lithium-ion batteries are widely used to

power devices from electric vehicles to portable electronics because they can

store a relatively large amount of energy in a relatively lightweight package.

The battery works by controlling the flow of lithium ions through a fluid

electrolyte between its two terminals, called the anode and cathode.

The promise—and peril—of using silicon as

the anode in these batteries comes from the way the lithium ions bond with the

anode during the charging cycle. Up to four lithium ions bind to each of the

atoms in a silicon anode—compared to just one for every six carbon atoms in

today’s graphite anode—which allows it to store much more charge.

However, it also swells the anode to as

much as four times its initial volume. What’s more, some of the electrolyte

reacts with the silicon, coating it and inhibiting further charging. When

lithium flows out of the anode during discharge, the anode shrinks back to its

original size and the coating cracks, exposing fresh silicon to the

electrolyte.

Within just a few cycles, the strain of

expansion and contraction, combined with the electrolyte attack, destroys the

anode through a process called “decrepitation.”

Over the past five years, Cui’s group has

progressively improved the durability of silicon anodes by making them out of

nanowires and then hollow silicon nanoparticles. His latest design consists of

a double-walled silicon nanotube coated with a thin layer of silicon oxide, a

very tough ceramic material.

This strong outer layer keeps the outside

wall of the nanotube from expanding, so it stays intact. Instead, the silicon

swells harmlessly into the hollow interior, which is also too small for

electrolyte molecules to enter. After the first charging cycle, it operates for

more than 6,000 cycles with 85% capacity remaining.

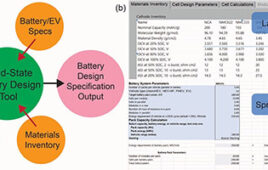

Cui said future research is aimed at

simplifying the process for making the double-wall silicon nanotubes. Others in

his group are developing new high-performance cathodes to combine with the new

anode to form a battery with five times the performance of today’s lithium-ion

technology.

In 2008,

Cui founded a company, Amprius, which licensed rights to Stanford’s patents for

his silicon nanowire anode technology. Its near-term goal is to produce a

battery with double the energy density of today’s lithium-ion batteries.