New Generation of Electrostatic Based Self-Cleaning Technology for Increasing Energy Yield from Dusty Solar Panels

Category: Mechanical/Materials

Developers: Superclean Glass Inc

Co-Developers: Stony Brook University

United States

Product Description:Superclean Glass has developed a new technology that has tremendous potential to reduce the cost of solar energy: New Generation of Electrostatic Based Self-Cleaning Technology for Increasing Energy Yield from Dusty Solar Panels. The original concept was used by NASA to prevent Martian dust deposition on solar panels of the Mars rovers, where the screen of conducting electrodes is incorporated into solar panels using parallel patterns. However, despite a solid scientific basis, this approach has never been made practical on Earth. The reasons are: (1) very high voltage requirements (kV) to clean the panels, thereby consuming energy and making it dangerous to operate; (2) low scalability of electrode deposition and patterning, making it too expensive for a very competitive PV market; (3) sub-optimal transparency of electrodes, thereby reducing the PV power output by over 30%. Superclean Glass has overcome all the previous limitations of NASA technology, making it practical in the terrestrial environment. In addition to 99% transparency, the company’s patent-pending solution has achieved an order of magnitude decrease in the required voltage as compared to that for NASA technology while simplifying pulsing sequence and circuitry.

Developers: Superclean Glass Inc

Co-Developers: Stony Brook University

United States

Product Description:Superclean Glass has developed a new technology that has tremendous potential to reduce the cost of solar energy: New Generation of Electrostatic Based Self-Cleaning Technology for Increasing Energy Yield from Dusty Solar Panels. The original concept was used by NASA to prevent Martian dust deposition on solar panels of the Mars rovers, where the screen of conducting electrodes is incorporated into solar panels using parallel patterns. However, despite a solid scientific basis, this approach has never been made practical on Earth. The reasons are: (1) very high voltage requirements (kV) to clean the panels, thereby consuming energy and making it dangerous to operate; (2) low scalability of electrode deposition and patterning, making it too expensive for a very competitive PV market; (3) sub-optimal transparency of electrodes, thereby reducing the PV power output by over 30%. Superclean Glass has overcome all the previous limitations of NASA technology, making it practical in the terrestrial environment. In addition to 99% transparency, the company’s patent-pending solution has achieved an order of magnitude decrease in the required voltage as compared to that for NASA technology while simplifying pulsing sequence and circuitry.

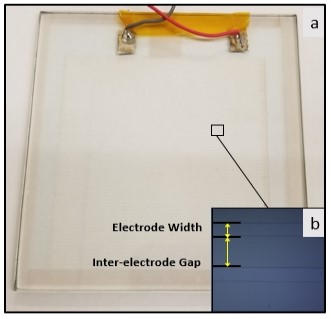

Modified Glass with Microscopy Images: see insert b