The Associated Press has reported that South Korean authorities were asked by electronics and semiconductor company Samsung to withhold critical information from workers and their families, after allegations that factory workers were exposed to deadly chemicals at the company’s computer chip and liquid crystal display factories.

There are over 200 current or former Samsung workers who have suffered from serious illnesses, mostly cancer or leukemia — 76 of these people have since died. Most employees involved in this initiative are in their 20s or 30s.

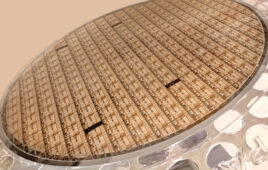

Read more: Samsung Opens Semiconductor Facilities to Inspection

Ill employees are supposed to be able to access data about these chemicals through the government or the courts, in order to provide proof when they apply for workers’ compensation from the state. Without this information, it’s next to impossible for people to get workers’ comp. However, court documents show that Samsung denied workers this information, alleging that doing so would expose trade secrets.

An attorney representing 15 ill Samsung employees says that his clients have not been able to get access to full reports on facility inspections — they are made by third parties to comply with South Korean law, but Samsung retains property of them. Court rulings only contain some excerpts of independent inspections.

South Korea law bans governments and public agencies from keeping corporate information secret, even out of fear of exposing trade secrets, if it is necessary “to protect the lives, physical safety, and health” of individuals. However, there aren’t any penalties for violations.

In a statement issued to the Associated Press, Samsung says it never “intentionally” blocked workers from accessing information, and that the company is transparent about all chemicals it is required to disclose.

A January 2016 post on Samsung’s website says that “of course” it is safe to work in the company’s semiconductor facilities, adding that, “We meet industry environment, health and safety (EHS) standards across all of our semiconductor fabrication plants, and our on-going ambition is to invest in finding better standards for ourselves and the industry. We have innovated many of the processes and controls that are now standard in the industry and continue to look for further enhancements.”