Utilizing tin oxide nanocrystals supported by a graphene structure, researchers have developed a new way to improve the performance of both sodium-ion and lithium-ion batteries.

Min-Kyu Song, an assistant professor in the Washington State University’s School of Mechanical and Materials Engineering, said in an interview with R&D Magazine that combining the power of tin oxide with a 3D graphene structure should be enough to enhance the performance of both types of batteries.

“We developed the bi-functional material that has shown good performance in both lithium-ion and sodium-ion batteries,” Song said. “The chemistry is pretty much similar, but the sodium ions are a little bit larger and heavier than lithium ions.

“Typically some materials that are good for lithium ions sometimes are not good for sodium ions,” he added. “But the tin oxide is the one that has shown good performance.”

With the new technology, sodium-ion batteries could prove to be a cheaper option to lithium-ion batteries, while also helping to solve material sustainability issues by alleviating the mining of lithium—which is considered a diminishing resource.

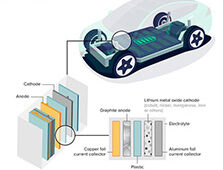

Lithium-ion batteries are often used in small portable electronics, as well as electric cars because they can store a high amount of energy in a small volume.

For sodium batteries, sodium-ions travel back and forth between the battery’s anode and cathode to produce electricity. While sodium batteries are attractive for mid-to-large-scale energy storage systems due to their low cost, they do not hold as much energy as lithium batteries. Manufacturers have sought ways to produce both lithium and sodium-ion batteries with only one type of anode material.

Tin oxide gives a battery’s anode the potential to store almost three times the energy of graphite that is typically used in batteries. While tin oxide is relatively easy to make, it often wears out quickly and stops working.

The researchers overcame this hurdle by making ultrafine nanocrystals of tin dioxide that were tightly bound to the 3D graphene structure. The hybrid structure is robust, well connected and porous, which allows for better transport of electrons and ions.

After testing the nanocrystals, the researchers found that the material improved the charging capacity and rate of both types of batteries.

“For electric vehicles, where you need a larger energy density we have to use lithium batteries,” Song said. “The problem is the cost of the lithium precursor.

“Sodium can be cheaper, but we don’t want to compromise the performance much,” he added. “We developed really good performance, so basically the sodium batteries can be used for different applications where we don’t need that high energy density.”

Song, who collaborated on the study with professor Yuehe Lin, said the research team is now working with funding agencies to make the new technology commercially viable.

The study was published in Nano Research.