Self-healing technology— which is becoming more common in the wearable devices and robotics industries— is now being utilized to improve the life of batteries.

A group of researchers from the University of Illinois at Urbana-Champaign have developed a battery that uses a silicon nanoparticle composite material on the anode—the negatively charged side of the battery—and a new way to hold the composite together, solving a frequent issue for batteries that contain silicon.

“This work is particularly new to self-healing materials research because it is applied to materials that store energy,” aerospace engineering professor Scott White said in a statement. “It’s a different type of objective altogether. Instead of recovering structural performance, we’re healing the ability to store energy.”

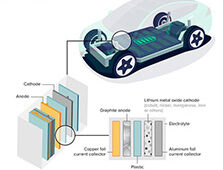

The anode, which is located inside the lithium-ion batteries that power portable devices and electric cars, are usually made from a graphite particle composite. This enables the battery to work well but also require lengthy charging and degrading over time.

“Silicon has such a high capacity, and with that high capacity, you get more energy out of your battery, except it also undergoes a huge volume expansion as it cycles and self-pulverizes,” materials science and engineering professor Nancy Sottos said in a statement.

While battery anodes made from nanosized silicon particles are less likely to degrade over time, they come with a host of other problems.

“You go through the charge-discharge cycle once, twice, three times and eventually you lose capacity because the silicon particles start to break away from the binder,” White said.

The researchers were able to refine the silicon anode by giving it the ability to heal itself through a reversible chemical bond at the interface between the silicon nanoparticles and the polymer binder. The new battery retained 80 percent of its original capacity, even after 400 charge cycles.

“This dynamic re-bonding process essentially holds the silicon particles and polymer binder together, significantly improving the long-term performance of the electrode,” Sottos said.

The battery also has a higher energy density that allows it to store more electricity than the graphite-anode based batteries.

“The higher the energy density, the better,” Sottos said. “The other option is to add more batteries, but that gets heavy and is an issue with electric cars, in particular.”

The study was published in Advanced Energy Materials.