Vanadium dioxide crystal lattice (A. Julia Stähler / Fritz Haber Institute) |

An

international team of physicists has developed a method for taking

ultrafast “sonograms” that can track the structural changes that take

place within solid materials in trillionth-of-a-second intervals as they

go through an important physical process called a phase transition.

Common

phase transitions include the melting of candle wax before it burns and

dissolving sugar in water. They are purely structural changes that

produce dramatic changes in a material’s physical properties and they

play a critical role both in nature and in industrial processes ranging

from steel making to chip fabrication.

The

researchers have applied this method to shed new light on the manner in

which vanadium dioxide, the material that undergoes the fastest phase

transition known, shifts between its transparent and reflective phases.

Many

of these transitions, like that in vanadium dioxide, take place so

rapidly that scientists have had difficulty catching them in the act.

“This means that there is a lot that we still don’t know about the

dynamics of these critical processes,” said Professor of Physics Richard

Haglund, who directed the team of Vanderbilt researchers who were

involved.

To

build a more complete picture of this phenomenon in vanadium dioxide

(VO2), one of the most unusual phase-change materials known, Vanderbilt

researchers collaborated with physicists at the Fritz Haber Institute of

the Max Planck Society in Berlin, who have developed the powerful new

technique for obtaining a more complete picture of ultrafast phase

changes. Details of the method, which can track the structural changes

that take place within materials at intervals of less than a trillionth

of a second, are reported in the Mar. 6 issue of the journal Nature Communications.

New details on nature’s quickest phase-change artist

Vanadium

dioxide shifts from a transparent, semiconducting phase to a

reflective, metallic phase in the time it takes a beam of light to

travel a tenth of a millimeter. This phase change can be caused by

heating the material above 150 F (65 C)

or by hitting it with a pulse of laser light.

VO2

is one of a class of materials now being considered for use in faster

computer memory. When mixed with suitable additives, it makes a window

coating that blocks infrared transmission on hot days and reduces heat

loss during cool periods. In addition, it has potential applications in

optical shutters, sensors and cameras.

“With

this new technique, we were able to see a lot of details that we’ve

never seen before,” said Haglund. These details include how the

electrons in the material rearrange first and then are followed by the

movement of the much more massive atoms as the material shifts from its

semiconductor to metallic-phase orientation. These details provide new

information that can be used to design high-speed optical switches using

this unique material.

Laser-based method tracks phase changes in ultra-short intervals

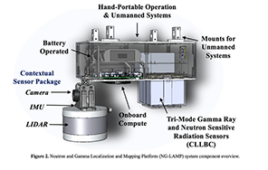

The

new method is a variation on a standard method known as

‘pump-and-probe.’ It uses an infrared laser that can produce powerful

pulses of light that only last for femtoseconds (millionths of a

trillionth of a second). When these pump pulses strike the surface of

the target material, they generate high-frequency atomic vibrations

determined by the material’s composition and phase. These vibrations

change during a phase transition so they can be used to identify and

track the transition in time.

At

the same time, the physicists split off a small fraction of the

infrared beam (the probe), convert it into white light and use it to

illuminate the surface of the target. It turns out that these lattice

vibrations produce changes in the material’s surface reflectivity. As a

result, the physicists can track what is happening inside the material

by mapping the changes taking place on its surface.

The

situation is analogous to hitting a gong with thousands of tiny

microscopic hammers. The sound each hammer makes depends on the

composition and arrangement of the atoms in the part of the gong where

it hits. If the composition and arrangement of the atoms changes in one

of these areas, then the sound the hammer makes also changes.

“The

real power of this technique is that it is sensitive to atomic changes

inside the material which are usually observed using expensive

large-scale X-ray sources. Now we can do the experiment optically and in

the lab on a tabletop,” said Simon Wall, an Alexander von Humbolt

fellow at the Fritz Haber Institute.

Vanderbilt

graduate students Kannatassen Appavoo and Joyeeta Nag fabricated and

characterized the vanadium dioxide thin films; Simon Wall, Daniel

Wegkamp, Laura Foglia, Julia Stähler and Martin Wolf at the Fritz Haber

Institute directed the laser experiments and subsequent data analysis.

The project was funded by grants from the Alexander von Humboldt Foundation and the National Science Foundation.

Ultrafast changes in lattice symmetry probed by coherent phonons