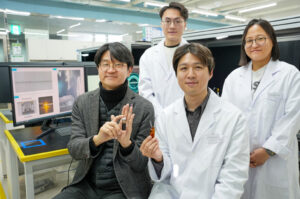

Seol Seung-kwon, Ph.D., (front row, left) and his team at the Korea Electrotechnology Research Institute (KERI) showcase their MXene-based 3D printing ink and nozzle.

Binders and viscosity hurdles have plagued micro-scale 3D printing in the past, often limiting results to “2D patterns or required diverse additives to produce 3D architectures,” as noted by researchers. But now, a team in South Korea has pioneered an additive-free method using the 2D nanomaterial MXene, achieving a 1.3-micrometer resolution—reportedly 270 times higher than existing techniques. This reserach, detailed in the journal Small, taps a ‘Meniscus’ printing approach and could help drive progress in manufacturing for next-generation batteries, sensors, and miniaturized electronic devices.

Developing the ‘Meniscus’ printing method

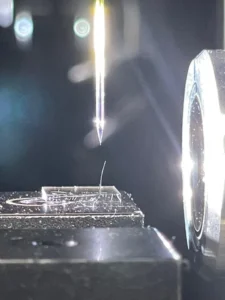

KERI’s 3D printer creating microstructures with MXene ink

Seol Seung-kwon’s team at the Korea Electrotechnology Research Institute (KERI) addressed specific processing hurdles with MXene. Conventional 3D printing approaches demanded binders, which unfortunately compromised MXene’s vital electrical conductivity and other characteristics. Achieving the correct ink consistency also proved challenging: high MXene concentrations clogged print nozzles, but low concentrations failed to produce stable structures.

To deal with such hurdles, KERI developed a ‘Meniscus’ printing method that controls the ejection of binder-free, water-based MXene ink. This method uses the meniscus—the curved surface of the liquid droplet—as a channel. Rapid solvent evaporation at this interface, combined with strong Van der Waals forces, allows MXene nanoparticles to self-assemble into solid structures without additives.

We put a lot of effort into optimizing the concentration conditions of MXene ink and precisely analyzing the various parameters that could arise during the printing process

High-resolution results

KERI’s 3D printing research results selected as the cover article in the journal Small.

This additive-free approach preserves pure MXene’s properties while enabling precisedesigns. The resulting 1.3 µm resolution enhances microfabrication capabilities. Seol noted, “”Our technology is the world’s first achievement that allows the creation of high-strength, high-precision 3D microstructures by leveraging the advantages of MXene without the need for any additives or post-processing.” This capability can enhance various applications: increasing energy density in batteries through greater surface area, improving electromagnetic shielding through absorption effects, and enhancing miniaturized sensors’ sensitivity and efficiency.

The KERI team plans to collaborate with industry partners to develop commercial applications. This pursuit meets a growing need for smaller, more flexible electronic devices. The research’s significance earned it a cover feature in Small. Support for this work came from KERI’s internal programs and a national project by the Ministry of Science and ICT focused on advanced manufacturing technologies.