Rice University materials scientists tested structures made of calcium-silicate nanoparticles and found that particles go from brittle to ductile as they increase in size. The compressed single particle at left deformed under the pressure of a nanoindenter. At center and right, large particles did not crack under pressure. Image: Courtesy of the Multiscale Materials Laboratory

Porous particles of calcium and silicate show potential as building blocks for a host of applications like self-healing materials, bone-tissue engineering, drug delivery, insulation, ceramics and construction materials, according to Rice University engineers who decided to see how well they perform at the nanoscale.

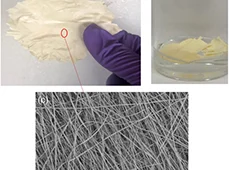

Following previous work on self-healing materials using porous building blocks, Rice materials scientist Rouzbeh Shahsavari and graduate student Sung Hoon Hwang made a wide range of porous particles between 150 and 550 nanometers in diameter — thousands of times smaller than the thickness of a sheet of paper — with pores about the width of a strand of DNA.

They then assembled the particles into micron-sized sheets and pellets to see how well the arrays held up under pressure from a nanoindenter, which tests the hardness of a material.

The results of more than 900 tests, reported this month in the American Chemical Society’s ACS Applied Materials and Interfaces, showed that bigger individual nanoparticles were 120 percent tougher than smaller ones.

This, Shahsavari says, was clear evidence of an intrinsic size effect where particles between 300 and 500 nanometers went from brittle to ductile, or pliable, even though they all had the same small pores that were 2 to 4 nanometers. But they were surprised to find that when the same big particles were stacked, the size effect didn’t carry over entirely to the larger structures.

The principles revealed should be important to scientists and engineers studying nanoparticles as building blocks in all kinds of bottom-up fabrication.

“With porous building blocks, controlling the link between porosity, particle size and mechanical properties is essential to the integrity of the system for any application,” Shahsavari says. “In this work, we found there is a brittle-to-ductile transition when increasing the particle size while keeping the pore size constant.

“This means that larger submicron calcium-silicate particles are tougher and more flexible compared with smaller ones, making them more damage-tolerant,” he says.

The lab tested self-assembled arrays of the tiny spheres as well as arrays compacted under the equivalent of 5 tons inside a cylindrical press.

Four sizes of spheres were allowed to self-assemble into films. When these were subject to nanoindentation, the researchers found the intrinsic size effect largely disappeared as the films showed variable stiffness. Where it was thin, the weakly bonded particles simply made way for the indenter to sink through to the glass substrate. Where it was thick, the film cracked.

“We observed that the stiffness increases as a function of applied indentation forces because as the maximum force is increased, it leads to a greater densification of the particles under load,” Shahsavari says. “By the time the peak load is reached, the particles are quite densely packed and start behaving collectively as a single film.”

Pellets made of compacted nanospheres of various diameters deformed under pressure from the nanoindenter but showed no evidence of getting tougher under pressure, they reported.

“As a next step, we’re interested in fabricating self-assembled superstructures with tunable particle size that better enable their intended functionalities, like loading and unloading with stimuli-sensitive sealants, while offering the best mechanical integrity,” Shahsavari says.

The National Science Foundation supported the research.

Source: Rice University