Stepped on by a hiking boot? Not a problem. Run over by a car? Good to go.

The appropriately named diabolical ironclad beetle can take a shelling thanks to the incredibly crush-resistant architecture of its exoskeleton, which could serve as the blueprints for designing tougher materials and stronger connections between different material types.

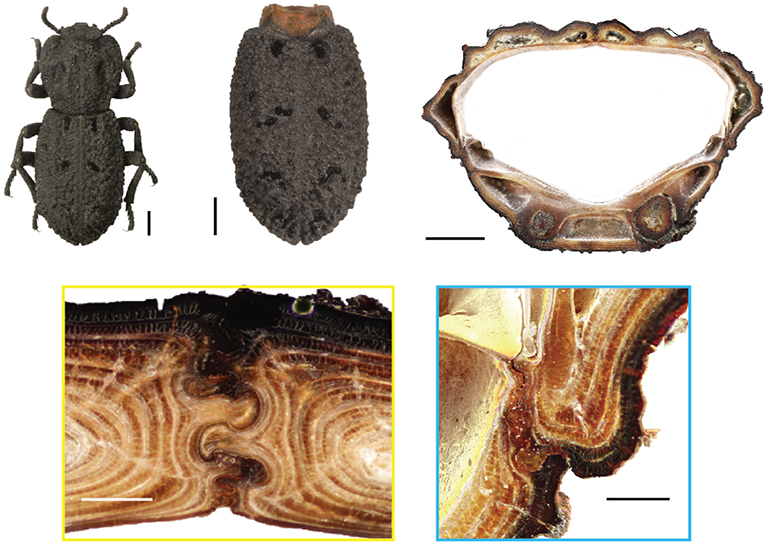

To see, in microscopic detail, what makes the beetle so uniquely ironclad, researchers used an X-ray imaging technique at Berkeley Lab’s Advanced Light Source (ALS) synchrotron, and other techniques, to explore a protective covering known as the “elytra,” its abdomen and other parts.

In flying beetles and other insects, the elytra serves as a cover for their wings, though the diabolical ironclad beetle is flightless and the researchers learned its elytra plays an important function in protecting its internal organs from crushing.

These images show the diabolical ironclad beetle (top left) and how its abdomen (top middle and right) contains an internal architecture (bottom) featuring puzzle-piece-like joints (bottom left) where the two halves of its exoskeleton join that make it incredibly crush-resistant. (Credit: UC Irvine)

“Being able to study the internal structure, in 3D and at high resolution, was critical to observing and understanding the structures,” said Dula Parkinson, an ALS staff scientist who was a co-author of the study, which was led by UC Riverside researchers and published in Nature.

Parkinson, along with ALS colleague and study co-author Harold Barnard, used a 3D imaging technique known as X-ray microtomography to see the beetle’s microscopic architecture – and especially the areas with interlocking parts – at different stages of compression.

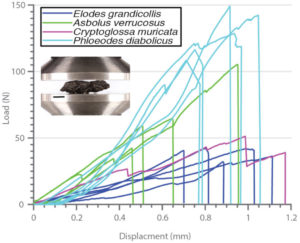

This chart shows how diabolical beetle (light blue lines) can withstand extreme compression compared to other types of beetles (green, dark blue, and purple lines). (Credit: UC Irvine)

The study found that diabolical ironclad beetles can withstand compression of up to 39,000 times their body weight – a load greater than an adult human can generate by pressing thumb and index finger together, and about 75% higher than comparable beetles can handle.

“The ALS was important to visualize internal fracture of the microstructure and capture possible toughening mechanisms,” said Jesus Rivera, the study’s lead author. Rivera participated in the study while at UC Riverside and is now at UC Irvine. “The combination of great personnel to help with equipment setup, fast scanning times and use of the mechanical stage allowed for a great experience that enabled this research.”

The ALS is a DOE Office of Science User Facility.

The study was supported by the Air Force Office of Scientific Research, the Army Research Office, and the Institute of Global Innovation Research at Tokyo University of Agriculture and Technology.

More:

Read a related UC Irvine press release about the study: “UCI materials scientists discover design secrets of nearly indestructible insect,” Oct. 21, 2020.

Tell Us What You Think!