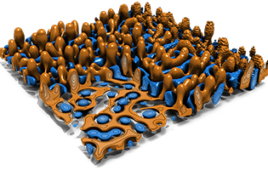

The “sweatainer” sensor. [Image courtesy of the University of Hawaiʻi at Mānoa College of Engineering]

Researchers at the University of Hawaiʻi at Mānoa College of Engineering say they developed a 3D-printed, wearable sweat sensor.

Called the “sweatainer,” the device harnesses the power of additive manufacturing to enable a new type of wearable sweat sensor. The researchers say the small, wearable device — similar in size to a child’s sticker — expands the capabilities of wearable sweat devices. Using various sensors, the device collects and analyzes sweat to enable health monitoring.

“3D-printing enables an entirely new design mode for wearable sweat sensors by allowing us to create fluidic networks and features with unprecedented complexity,” Department of Mechanical Engineering Assistant Professor Tyler Ray said. “With the sweatainer, we are utilizing 3D-printing to showcase the vast opportunities this approach enables for accessible, innovative and cost-effective prototyping of advanced wearable sweat devices.”

According to the researchers, traditional methods for sweat collection use absorbent pads of microbore tubes. Using bands or straps to press against the epidermis, these pads or tubes capture sweat as it emerges from the skin. These techniques need trained personnel, special handling and costly laboratory equipment.

While wearable sensors address some hurdles in sweat collection, they remain single-use, the researchers say. Once the device is full, it must be removed and sweat collection must cease.

The Hawaii team’s sweatainer features a “multi-draw” collection method. It can collect multiple, separate sweat samples for analysis, both directly on the device or via the lab. Researchers say this not only makes the process more efficient but opens up new possibilities like at-home testing, storing samples for future research and integrating with existing health monitoring methods.

Researchers say field studies demonstrated real-world potential for the technology. They hope to “continue to drive innovation to create a future where personal health monitoring is more accessible, convenient and insightful.”