From Argonne National Laboratory, a 2021 R&D 100 winner

Manufacturing is a truly time-consuming and cost-intensive process. To optimize the design of a new product, manufacturers typically undergo round after round of experimental trials and iterative prototype evaluation.

However, as the volume and complexity of data increases, industry leaders are increasingly turning to high-fidelity computer models to create virtual representations of real-world systems and devices. Still, even these standards for design remain remarkably slow.

With advances in computational science, specifically machine learning, scientists have acquired a new tool in their toolkit to dramatically speed up product design and manufacturing, cutting months off the time it takes for new products to reach consumers.

Scientists at the U.S. Department of Energy’s Argonne National Laboratory have developed a new kind of machine learning technology called machine learning-genetic algorithm (ML-GA) that fuses machine learning (ML) and evolutionary genetic algorithms (GA) to reduce the amount of time it takes to arrive at an optimal design from months to days, which leads to faster technology development and faster delivery of designs to consumers.

This new approach recently garnered a 2021 R&D 100 award, commonly referred to as the “Oscar of Innovation.”

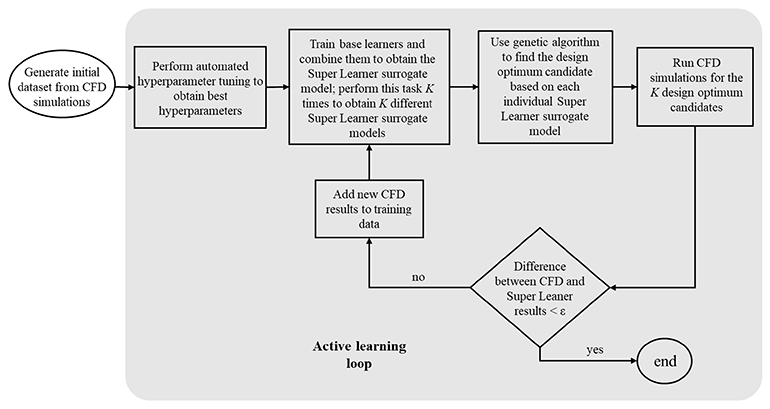

The difference between ML-GA and more traditional optimization methods is that Argonne’s software learns from simulation data adaptively. For ML-GA, scientists run simulations in small batches — called iterations — and train a ML surrogate model on the simulation data. This surrogate model serves as a replacement for the simulation itself within a GA optimization pipeline. As a result, the overall runtime is greatly reduced by this much faster surrogate model.

“ML-GA is a one-of-its-kind software technology that brings to bear the power of advanced machine learning for virtual design optimization of products and manufacturing processes across a wide range of industries,” said Argonne research scientist Pinaki Pal, who also led the R&D 100 award-winning team that developed ML-GA. The team also includes Argonne principal computational scientist Sibendu Som, and former Argonne researchers, Opeoluwa Owoyele (postdoctoral appointee), Ahmed Abdul Moiz (postdoctoral appointee) and Janardhan Kodavasal (research scientist).

The approach is not without its challenges. ML surrogate models may require a lot of simulation training data to achieve high accuracy. To deal with this, ML-GA uses a “Super Learner” framework which combines multiple ML algorithms to make predictions more accurate than those made by each individual ML algorithm. In addition, the model uses an active learning technique to select the best possible design points to simulate during each successive iteration.

The ML-GA technology has already found its way into the marketplace. In January 2021, it was licensed on a nonexclusive basis by Parallel Works, a start-up high-performance computing (HPC) software platform company in Chicago. The technology transfer allowed Parallel Works to integrate ML-GA into its commercial platform within a new add-on package called Learner Works.

This integrated platform has already attracted early adopters and evaluators from a wide range of manufacturing industries, including Tier 1 automotive original equipment manufacturers (OEMs), R&D companies making defense equipment and systems, major manufacturers of heavy vehicles for agriculture and construction and enterprises that perform hydrological engineering and management of river system watersheds.

“Because it is both highly parallelizable and portable, ML-GA can be readily coupled with any simulation tool and run efficiently on high-performance computers and cloud-based platforms,” said Pal. These unique features allow for easy adoption by industries ranging from automotive, aerospace and defense to energy and oil and gas.

“As a result of its innovative features, ML-GA offers the capability to drastically shrink product design cycles and costs for industry,” said Sibendu Som.

Development and commercialization of ML-GA was funded with support from Department of Energy’s (DOE) Vehicle Technologies Office (VTO) through a Technology Commercialization Fund (TCF) project. VTO is part of the DOE’s Office of Energy Efficiency and Renewable Energy (EERE).

Tell Us What You Think!