By Jeaneen Kulp, Jackson ImmunoResearch for BRANDTECH Scientific

Introduction

Jackson ImmunoResearch saw a need to monitor antibody performance at sequential stages of production. Antibody characterization was previously done using a time consuming, complex and physically demanding method which constrained testing to the final step in the process. This led to the loss of valuable decision-making opportunities along the way which could improve product quality and efficiencies in manufacture. To solve this problem, Jackson ImmunoResearch’s Quality Assurance department developed an automated assay using the Brand Liquid Handling Station.

Currently, the Quality Assurance department runs about 10-15 samples per week utilizing this new assay. This workload is added on to the requirements of an already busy group. The hope is that this test becomes integrated into the production process. This could potentially double the frequency of testing.

Jackson ImmunoResearch wanted to take pressure off technicians by automating this testing procedure. The expectation is to ensure precise results that are repeatable and consistent. Using a robot reduces the opportunity for human error. It also frees up technicians to be able to get other work done while the robot is working. Repetitive motion tasks are reduced for a technician as well.

As a first step, an inexpensive liquid handler was purchased to prove that automating this procedure was achievable and would be beneficial. The operation of the robot required a QA technician to learn computer coding in order to develop and execute protocols within the operation software. The robot’s software was not intuitive and writing each program was very tedious. After working with the robot for almost a year, it never functioned correctly due to manufacturing and design issues. However, it did function well enough to provide successful proof of concept testing. Jackson ImmunoResearch then decided to look for a system that was easy to use, reliable, and affordable. The BRAND® Liquid Handling Station (LHS) seemed promising. Following a successful demo of the LHS, the instrument was purchased and put right to work.

Benefits of using the LHS

Programming this robot is incredibly intuitive. This benefits bench scientists who usually don’t have a formal education in computer coding. To be able to drag and drop onto a virtual deck that looks just like the real thing and adjust all aspects of set-up easily makes programming stress free. After the program is written, checking the efficiency and accuracy of the new protocol can be done with the simulate feature. This allows the user to catch mistakes before utilizing samples and consumables on an errant program. One of the most helpful features incorporated into the dilution program was being able to add a pause into the protocol. The pause was added with an instruction to wash and add the ELISA plate to the appropriate deck position. This way, the ELISA plate did not sit on the deck dry after being washed, waiting for the robot to dilute the samples.

Results summary

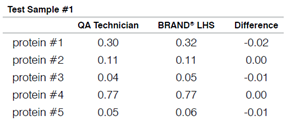

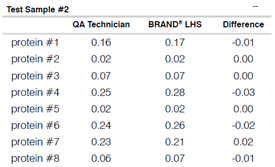

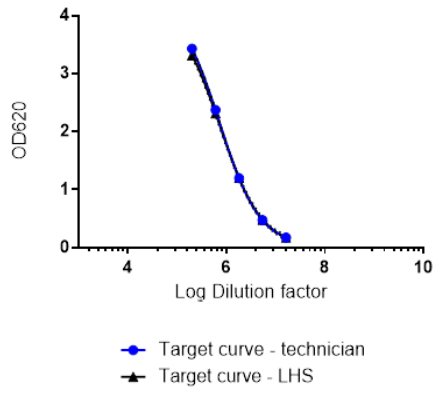

The LHS performed the ELISA very similarly to a technician. Below shows a summary of the results and compares the two methods. As is evident with the data analyses, these two curves and the ODs from the samples relate to each other in the same way regardless of whether a person is running the test or the LHS is doing the pipetting.

Summary

For Jackson ImmunoResearch, integrating the BRAND® Liquid Handling Station into the testing repertoire seemed like a logical next step to continually improve testing methods and optimize production. This particular robot allows for intuitive programming and accurate pipetting. These features help free up time for a technician to be able to complete a task while the LHS easily performs another.

LEARN MORE about the BRAND® LHS, consult with our team on how the robot can support your lab or request a demo today!

The LHS is available from BRANDTECH® Scientific the US and Canadian division of the BRAND® Group representing BRAND®, VACUUBRAND® and Vitlab® products.

Target protein curves plotted from the QA Technician’s data and the LHS’s data also look very similar.

QA technician vs LHS:

Sponsored content by BRANDTECH Scientific

Tell Us What You Think!