An ultralight high-performance mechanical watch made with graphene has been unveiled in Geneva at the Salon International De La Haute Horlogerie thanks to a unique collaboration.

The University of Manchester has collaborated with watchmaking brand Richard Mille and McLaren F1 to create world’s lightest mechanical chronograph by pairing leading graphene research with precision engineering.

The RM 50-03 watch was made using a unique composite incorporating graphene to manufacture a strong but lightweight new case to house the delicate watch mechanism. The graphene composite known as Graph TPT weighs less than previous similar materials used in watchmaking.

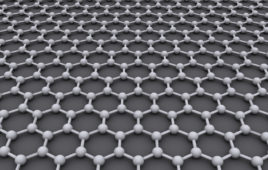

Graphene is the world’s first two-dimensional material at just one-atom thick. It was first isolated at The University of Manchester in 2004 and has the potential to revolutionize a large number of applications including, high-performance composites for the automotive and aerospace industries, as well as flexible, bendable mobile phones and tablets and next-generation energy storage.

The strap of the new watch has also been improved by the addition of graphene material. The rubber of the strap was also injected with graphene which has shown to improve its mechanical properties and its resistance to wear.

Overall the ultralight watch weighs just 40 grams and is extremely durable. The details of the collaboration and the new watch were unveiled today in Geneva by; Richard Mille, Zak Brown, McLaren F1 CEO, Eric Boullier, McLaren F1 Racing Director and new McLaren-Honda F1 driver Stoffel Vandoorne. James Baker, Graphene Business Director and Professor Robert Young from The University of Manchester provided insights into the benefits of using graphene.

Young, Professor of Polymer Science and Technology at the University, says of the collaboration: “The project with McLaren and Richard Mille involved an investigation into the possibility of incorporating graphene into components in composite watches to enhance performance with the view of saving weight.

“We evaluated the effect of including graphene in both the watch case and strap. We helped in the fabrication of the different components and analyzed their microstructures using x-ray computed tomography and Raman spectroscopy, along with a detailed evaluation of their mechanical properties.

“We have shown that the incorporation of graphene into the watch case can have major implications for improved performance of the component in service and also enable further weight reduction in future designs.”

The striking watch has been precisely designed and inspired by the wishbone suspension structure of a McLaren-Honda Formula 1 car. Combining the design and materials the casing of the watch has withstood tremendous shock damage and survived unscathed in tests.

Speaking about the RM 50-03 watch, Mille says, “McLaren were already pioneers in the application of carbon to F1 cars back in the 1980s, and many aspects of our approach dovetailed nicely. We share the same desire to combine lightness and speed with durability.

“Via McLaren Applied Technologies, McLaren is deeply involved in research and development beside the automotive industry. This was an opportunity for us to discover the applications of graphene and to apply it for the case of the watch, a world first premiere. The RM 50-03 represents a new approach to the challenges of lightness underlying our watchmaking philosophy.”

James Baker, Graphene Business Director, The University of Manchester, says, “This collaboration has brought together three leading organizations who strive for excellence and perfection in their fields.

“The results from this project have shown exactly why graphene is perfect for delivering improvements where high-performance materials are necessary and is a key step forward into developing more widespread applications including automotive and aerospace.”

Source: University of Manchester