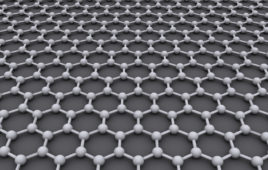

Layered transition metal dichalcogenides or TMDCs—materials composed of metal nanolayers sandwiched between two other layers of chalcogens— have become extremely attractive to the research community due to their ability to exfoliate into 2D single layers.

Similar to graphene, they not only retain some of the unique properties of the bulk material, but also demonstrate direct-gap semiconducting behavior, excellent electrocatalytic activity and unique quantum phenomena such as charge density waves (CDW).

Generating complex multi-principle element TMDCs essential for the future development of new generations of quantum, electronic, and energy conversion materials is difficult.

“It is relatively simple to make a binary material from one type of metal and one type of chalcogen,” says Ames Laboratory Senior Scientist Viktor Balema.

“Once you try to add more metals or chalcogens to the reactants, combining them into a uniform structure becomes challenging. It was even believed that alloying of two or more different binary TMDCs in one single-phase material is absolutely impossible.”

To overcome this obstacle, postdoctoral research associate Ihor Hlova used ball-milling and subsequent reactive fusion to combine such TMDCs as MoS2, WSe2, WS2, TaS2, and NbSe2. Ball-milling is a mechanochemical process capable of exfoliating layered materials into single- or few-layer-nanosheets that can further restore their multi-layered arrangements by restacking.

“Mechanical processing treats binary TMDCs like shuffling together two separate decks of cards,” says Balema.

“They are reordered to form 3D-heterostructured architectures — an unprecedented phenomenon first observed in our work.”

Heating of the resulting 3D-heterostructures brings them to the edge of their stability, reorders atoms within and between their layers, resulting in single-phase solids that can in turn be exfoliated, or peeled into 2D single layers similar to graphene, but with their own, unique tunable properties.

“Preliminary examination of properties of only a few, earlier unavailable compounds, proves as exciting as synthetic results are,” adds Ames Laboratory Senior Scientist and Distinguished Professor of Materials Science and Engineering Vitalij Pecharsky.

“Very likely, we have just opened doors to the entirely new class of finely tunable, quantum matter.”

This research was supported by the Ames Laboratory’s Directed Research and Development program under contract with the U.S. Department of Energy.

The research is further discussed in the paper, “Multi-Principal Element Transition Metal Dichalcogenides via Reactive Fusion of 3D-Heterostructures,” authored by Ihor Z. Hlova, Oleksandr Dolotko, Brett W. Boote, Arjun K. Pathak, Emily A. Smith, Vitalij K. Pecharsky, and Viktor P. Balema; and published on the cover of Chemical Communications.

Source: Ames Laboratory