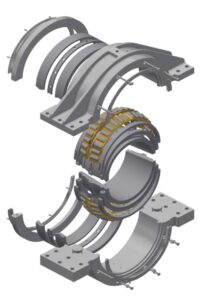

The Timken Split Tapered Roller Bearing for Mainshaft is designed for uptower installation in wind turbine nacelles. Non-split solid ring bearings require expensive ground-based cranes for bearing replacement. The Timken product has two halves that are installed using smaller uptower cranes and no blade removal, dramatically reducing costs and downtime.

The Timken Split Tapered Roller Bearing for Mainshaft is designed for uptower installation in wind turbine nacelles. Non-split solid ring bearings require expensive ground-based cranes for bearing replacement. The Timken product has two halves that are installed using smaller uptower cranes and no blade removal, dramatically reducing costs and downtime.

Most wind turbines operate under very demanding conditions in remote areas and in harsh environments where access to repair equipment is generally not readily available. Therefore, it is important for wind turbine machine components, including bearings, to have long lives and be easy to replace if they become damaged with use.

Developing a bearing that is significantly less expensive to replace is beneficial to wind farm operators. The Timken split tapered roller bearing enables maintenance to replace faulty or damaged mainshaft bearings uptower without the need for expensive ground-based cranes. Smaller uptower-mounted cranes are all that is needed. The split bearing design prevents the need for blade removal, saving time and money and reducing risk of assembly errors.

Tell Us What You Think!