A Q&A with David Bentley, Protolabs

Digital manufacturing leader Protolabs has invested heavily in additive manufacturing equipment, with a concentration in laser powder-bed fusion (LPBF) technology. The company recently purchased their first Sapphire metal AM machine from Velo3D to explore its advanced SupportFree capabilities.

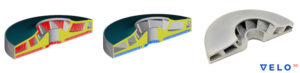

An impeller is an example of a part design that has not been producible additively without major modifications to the design to facilitate support structure removal. By eliminating support structures throughout the interior, metal AM now has a strong business case for impellers, and many more part categories. Photo Credit: Velo3D

Since the earliest days of additive manufacturing (AM), support structures have been a nuisance, impedance, or problem. Whether printing with plastics or metals, very few AM technologies have been able to avoid building parts without them. The need for support structures adds unwanted challenges when designing them, printing them, and removing them.

Presently, nearly all metal AM systems based on the laser powder bed fusion (LPBF) class of technology have the requirement for support structures to be added to parts. Generally, these AM processes require supports on all downfacing surfaces that are printed at an angle of less than 45 degrees from the horizontal plane, which is established by the build plate.

David Bentley, senior manufacturing engineer for 3D printed metals at Protolabs, responded to a recent Q&A with some insights into when support structures have the most impact, how elimination translates to benefits, and the best use cases.

Q: How does eliminating support structures impact turnaround time and cost reduction for Protolabs?

Bentley: Eliminating support structures certainly reduces lead time and decreases the expense of printing. Over 95% of the parts that I see in my role require support removal. Considering the resources needed to remove those supports and the associated costs, there’s certainly a business case for cost savings and labor savings.

But, after discovering the full impact of a support-less metal AM process, the most compelling reason was that there are some big, high-value parts that simply can’t be produced without a support-less process. Our aerospace customers are really excited about the support-less printing process and quality-control software, because it’s the complete package: good parts, good parameters, repeatability and comprehensive tracking and reporting of what’s going on through the process. And for Protolabs, expanding into the aerospace industry is really interesting so having this advanced technology helps us serve that customer base.

Eliminating support structures in AM provides geometric enablement, enabling the printing of parts that would typically fail in the LPBF process. Parts with characteristics of high aspect ratio, steep overhangs, and complex internal passageways are all good candidates. Photo Credit: Velo3D

Q: How does eliminating support structures lead to quality improvement?

Bentley: Anybody who is experienced with metal AM systems has seen firsthand that support elimination improves part quality. Those that have not been exposed to the metal AM workflow may not appreciate that support structures have a significant, and very visible, effect.

When you have supported surfaces, part aesthetics are compromised after you remove the supports. There is the aspect of having to do the work to remove the supports, but there’s also the quality to consider. If you can have more surfaces that are untouched, you are just going to have a better part. And that’s something that I think Protolabs really values. We want to have the best-looking parts out there.

For example, one of our customers has a requirement for consistent surface finish all the way up, and their part has some angles a bit below 45 degrees that would usually require support. These surfaces needed to be consistent with those on unsupported side walls. This was only possible with the elimination of support structures.

Angles below 45 degrees require support structures to ensure stability of the part during the printing process. As the angle decreases, the downward-facing surface becomes rougher and eventually will fail if the angle is reduced too far. Photo Credit: Proto Labs

Q: How does eliminating support structures enable you to print parts you couldn’t before?

Bentley: The best part candidates are ones with inlets, outlets, and manifold-like structures between these points of accessibility. Examples include shrouded impellers, heat exchangers, and manifolds; essentially anything with complex internal passageways. Support removal can be difficult, impractical, and even impossible due to the lack of accessibility. A lot of those parts are still manufactured via traditional methods. Support-reducing technology really opens up the ability to print those types of designs with much less risk.

Also, the unique noncontact recoating technology of the Sapphire machine we’ve just purchased allows you to pretty much build a half-a-millimeter stick that is fourteen inches tall. We don’t have to worry about any height to width ratio anymore. That type of geometry would typically fail in the LPBF process.

David Bentley was one of the six experts that Todd Grimm interviewed for his whitepaper titled “The Business Impact of a Support-Less Process for Metal AM.” To learn more about his insights and experiences with a support-less process, please download the whitepaper here at events.velo3d.com/supportfree-whitepaper-todd-grimm

Tell Us What You Think!