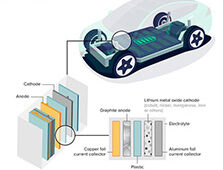

A new type of auminum-air flow battery, which is more energy efficient than the existing LIBs. Credit: UNIST

A silver manganate nanoplate has enabled scientists to create a safer, more energy efficient aluminum-based air flow battery at a lower cost.

Researchers from the Ulsan National Institute of Science and Technology have used the new catalyst to develop an aluminum-air flow battery that could enable electric vehicle drivers to have battery packs that have a longer range and can be replaced, rather than deal with slow charging, a problem that is common with existing EV battery technology.

The new battery, when compared to existing lithium-ion batteries, features a higher energy density, lower cost, longer cycle life and higher safety. It is also lightweight with little risk of catching fire or exploding.

Aluminum-air batteries cannot be recharged through conventional means because they are primary cells. When applied to electric vehicles, the batteries produce electricity by simply replacing the aluminum plate and electrolyte. Aluminum is preferred over gasoline due the actual energy density of the two materials at the same weight.

“Gasoline has an energy density of 1,700 Wh/kg, while an aluminum-air flow battery exhibits a much higher energy densities of 2,500 Wh/kg with its replaceable electrolyte and aluminum,” professor Jaephil Cho said in a statement. “This means, with one kg of aluminum, we can build a battery that enables an electric car to run up to 700 km.”

The team was able to increase the discharge capacity of their battery 17 times as compared to conventional aluminum air batteries.

Similar to how other metal-air batteries operate, the new battery produces electricity from the reaction of oxygen in the air with aluminum. While aluminum-air batteries feature one of the highest energy densities of all batteries, they are not widely used due to problems with high anode costs and byproduct removal issues when using traditional electrolytes.

To overcome this hurdle, the researchers developed a battery that can alleviate the side reactions in the cell where the electrolytes can be circulated continuously.

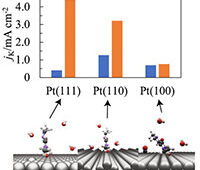

The researchers prepared a silver nanoparticle seed-mediated silver manganite nanoplate architecture for the oxygen reduction reaction and found that the silver atom migrates into the available crystal lattice and rearrange the manganese oxide structure to create abundant surface dislocations.

The battery’s improved longevity and energy density could help bring more electric vehicles to the road with a greater range at a substantially lighter weight without the risk of explosions occurring.

“This innovative strategy prevented the precipitation of solid by-product in the cell and dissolution of a precious metal in air electrode,” Jaechan Ryu, first author of the study, said in a statement. “We believe that our AAFB system has the potential for a cost-effective and safe next-generation energy conversion system.”

The study was published in Nature Communications.