Using a new approach, the team built a graphene membrane for use in lithium-air batteries, which could, one day, replace conventional batteries in electric vehicles. Resembling coral, this porous graphene material could replace the traditional smooth graphene sheets in lithium-air batteries, which become clogged with tiny particles during use. |

Resembling broken eggshells, graphene structures built

around bubbles produced a lithium-air battery with the highest energy capacity

to date, according to scientists at Pacific Northwest National Laboratory and Princeton University. This black, porous material

could replace the traditional smooth graphene sheets in lithium-air batteries,

which become clogged with tiny particles during use. As an added bonus, the

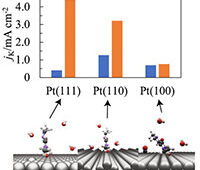

team’s new material does not rely on platinum or other precious metals,

reducing its potential cost and environmental impact.

“This hierarchical structure of self-assembled graphene

sheets is an ideal design not only for lithium-air batteries but also for many

other potential energy applications,” says Jie Xiao, the materials

scientist at PNNL who led the study.

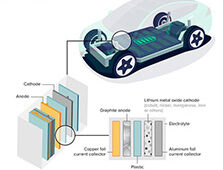

Lithium-air batteries could allow for the creation of

long-range electric vehicles, able to travel up to 300 miles

between charges. Comparatively lightweight, lithium-air batteries still suffer

from limited practical capacity and poor cycle life issues. However, this study

showed how to maximize the capacity of the batteries.

“This is critical for applications, including electric

vehicles and energy storage,” says Jun Liu, a materials scientist on the

study and Director of PNNL’s Transformational Materials Science Initiative,

which funded the research.

The team began by combining a binding agent with graphene.

The binding agent dispersed the graphene in solution, like soap disperses

grease in dishwater. The graphene and binder were then added to water and mixed

using a process that created bubbles inside the solution. The graphene and

binder formed and hardened around the bubbles. When the bubbles eventually

popped, hollow spheres of graphene were left behind. The tiny black particles

are only 3 to 4 um in diameter.

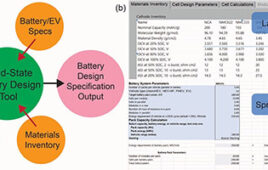

Using both modeling and microscopy, the scientists analyzed

the graphene structures and their performance. They performed density

functional theory calculations on the supercomputing system at the National Energy Research

Scientific Computing

Center. They studied the

particles using electron microscopy at the Environmental Molecular Sciences

Laboratory.

The researchers found that the black porous structures store

more than 15,000 milliamp hours per gram of graphene, making it far denser in

term of energy capacity than other materials.

“Many catalysts are studied now for this technology. In

our process we chose not to use precious metal,” says Ji-Guang Zhang, the

group leader in PNNL’s Li-air battery research. “This will greatly reduce

production costs and increase the adoptability.”

The battery is achieving the highest levels of energy

capacity in an oxygen-only environment. When operated in ambient air, the capacity

drops because the water in the air fouls the lithium metal in the batteries.

The PNNL team is working to develop a membrane to block the water and still

allow the necessary oxygen to flow.

“We also want to make the battery rechargeable,”

says Zhang. “Right now, it is not. It is not fully rechargeable. We are

working on a new electrolyte and a new catalyst so that the battery can be

recharged multiple times, potentially for battery backup applications that

require high energy densities.”