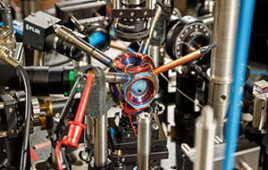

Micrographs of the diamond MEMS chip developed through this research and one of the diamond cantilevers integrated into the chip. Image: NIMS

A NIMS-led research group succeeded in developing a high-quality diamond cantilever with among the highest quality (Q) factor values at room temperature ever achieved.

The group also succeeded for the first time in the world in developing a single crystal diamond microelectromechanical systems (MEMS) sensor chip that can be actuated and sensed by electrical signals. These achievements may popularize research on diamond MEMS with significantly higher sensitivity and greater reliability than existing silicon MEMS.

In MEMS sensors, microscopic cantilevers (projecting beams fixed at only one end) and electronic circuits are integrated on a single substrate. They have been used in gas sensors, mass analyzers and scanning microscope probes. For practical application in a wider variety of fields, including disaster prevention and medicine, they require greater sensitivity and reliability.

The elastic constant and mechanical constant of diamond are among the highest of any material, making it promising for use in the development of highly reliable and sensitive MEMS sensors. However, three-dimensional microfabrication of diamond is difficult due to its mechanical hardness. The research group developed a “smart cut” fabrication method that enabled microprocessing of diamond using ion beams and succeeded in fabricating a single crystal diamond cantilever in 2010.

However, the quality factor of the diamond cantilever was similar to that of existing silicon cantilevers because of the presence of surface defects.

The research group subsequently developed a new technique enabling atomic-scale etching of diamond surfaces. This etching technique allowed the group to remove defects on the bottom surface of the single crystal diamond cantilever fabricated using the smart cut method. The resulting cantilever exhibited Q factor values—a parameter used to measure the sensitivity of a cantilever—greater than one million; among the world’s highest.

The group then formulated a novel MEMS device concept: simultaneous integration of a cantilever, an electronic circuit that oscillates the cantilever and an electronic circuit that senses the vibration of the cantilever.

Finally, the group developed a single crystal diamond MEMS chip that can be actuated by electrical signals and successfully demonstrated its operation for the first time. The chip exhibited very high performance and sensitivity, operating at low voltages and at temperatures as high as 600 C.

These results may expedite research on fundamental technology vital to the practical application of diamond MEMS chips and the development of extremely sensitive, high-speed, compact and reliable sensors capable of distinguishing masses differing by as light as a single molecule.