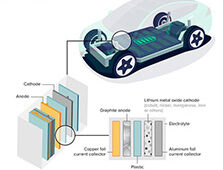

Lithium (Li)-ion batteries power almost all of the portable electronic devices that we use every day, including smartphones, cameras, toys and even electric cars. Researchers across the globe are working to find materials that will lead to safe, cheap, long-lasting and powerful Li-ion batteries.

Lithium (Li)-ion batteries power almost all of the portable electronic devices that we use every day, including smartphones, cameras, toys and even electric cars. Researchers across the globe are working to find materials that will lead to safe, cheap, long-lasting and powerful Li-ion batteries.

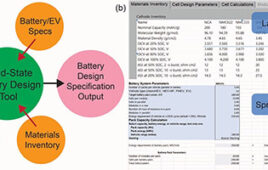

Working at various U.S. Dept. of Energy (DOE) light source facilities and at Cambridge and Stony Brook universities, a group of researchers recently studied a class of Li-ion battery electrodes that have capacities much greater than those of the materials used in today’s batteries. The researchers wanted to determine why these materials can often store more charge than theory predicts.

The authors chose ruthenium oxide (RuO2) as a model system to study these so-called “conversion materials,” named because they undergo large structural changes when reacting with lithium ions, reversibly forming metal nanoparticles and salts (here Ru and Li2O). These reactions are very different from those that occur in conventional electrodes, which store charge by allowing Li ions to nestle into spaces within the crystal lattice.

“Our investigation identified the source of the additional capacity found for RuO2, and has also yielded a protocol for studying the ‘passivation layer’ that forms on battery electrodes, which protects the electrolyte from undergoing further decomposition reactions in subsequent charge-discharge cycles,” said the study’s corresponding researcher, Clare Grey, a professor in the chemistry departments at Cambridge and Stony Brook universities. “Understanding the structures of these passivation layers is key to making batteries that last long enough for use in applications such as transportation and power-grid storage.”

At Brookhaven National Laboratory’s National Synchrotron Light Source, the team studied their samples using x-ray absorption near-edge structure (XANES) and extended x-ray absorption fine structure (EXAFS). At the Advanced Photon Source at Argonne National Laboratory, they used two additional techniques, high-resolution x-ray diffraction (XRD) and scattering pair distribution function (PDF) analysis, to extract information on the electronic and long/short-range structural changes of the RuO2 electrode in real time as the battery was discharged and charged. Using these methods, the team showed that RuO2 was reduced to Ru nanoparticles and Li2O via the formation of intermediate phases, LixRuO2.

Since this did not explain the source of the additional charge-storage mechanism, the group used another technique, high-resolution solid-state nuclear magnetic resonance (NMR). This method involves subjecting a sample to a magnetic field and measuring the response of the nuclei within the sample. It can yield specific information on the chemical compositions and local structures, and is particularly useful for studying compounds that contain only “light” elements, such as hydrogen (H), Li, and oxygen (O), which are difficult to detect using XRD. The NMR data showed that the major contributor to the capacity is the formation of LiOH, which reversibly converts to Li2O and LiH. Minor contributors to the capacity come from Li storage on the Ru nanoparticle surfaces, forming a LixRu alloy, and the decomposition of the electrolyte. The latter, however, ultimately causes the capacity to diminish and will result in the death of the battery following multiple charge cycles.

Source: Brookhaven National Laboratory