An innovative new cheap and simple mass production technique, developed by the University of Exeter, is set to open up the global potential of the “wonder” material graphene.

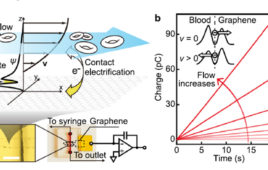

A team of engineers from Exeter’s Centre for Graphene Science has developed a new method for creating entire device arrays directly on the copper substrates used for the commercial manufacture of graphene. Complete and fully-functional devices can then be transferred to a substrate of choice, such as silicon, plastics, or even textiles.

Professor David Wright, from Exeter’s Engineering department and one of the authors, says, “The conventional way of producing devices using graphene can be time-consuming, intricate and expensive and involves many process steps including graphene growth, film transfer, lithographic patterning and metal contact deposition. Our new approach is much simpler and has the very real potential to open up the use of cheap-to-produce graphene devices for a host of important applications from gas and bio-medical sensors to touch-screen displays.”

To demonstrate the new process, the team have produced a flexible and completely transparent graphene-oxide based humidity sensor that would cost pennies to produce using common wafer-scale or roll-to-roll manufacturing techniques, yet can outperform currently available commercial sensors.

The new research features in the latest online edition of the Institute of Physics’ respected journal, 2D Materials.

Professor Monica Craciun, also from Exeter’s engineering department and co-author, adds, “The University of Exeter is one of the world’s leading authorities on graphene, and this new research is just the latest step in our vision to help create a graphene-driven industrial revolution. High-quality, low cost graphene devices are an integral part of making this a reality, and our latest work is a truly significant advance that could unlock graphene’s true potential.”

The Exeter engineering team consisted of Dr. Arseny Alexeev, Matthew Barnes, Dr. Karthik Nagareddy, and Professors Craciun and Wright, and the work was carried out as part of the EU-funded FP7 project CareRAMM.

“A simple process for the fabrication of large-area CVD graphene based devices vie selective in situ functionalization and patterning” is published in 2D Materials online.

Source: University of Exeter