DOWSIL VE-8001 Flexible Silicone Adhesive is a primerless adhesive that supports low temperature curing and has stable mechanical properties.

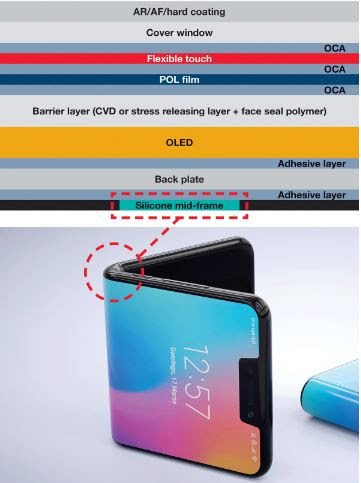

Dow (NYSE: Dow) introduced today new DOWSIL VE-8001 Flexible Silicone Adhesive for flexible and foldable displays, smartphones, wearables, laptops, televisions and many other types of electronic devices. This two-part primerless silicone adhesive is applied directly to thin metal surfaces and forms an elastic layer, or inner hinge, that helps to protect the display from damage caused by folding and unfolding. DOWSIL VE-8001 Flexible Silicone Adhesive is easy to apply, features low temperature curing for reduced energy costs and provides durable mechanical properties. Its tensile strength and elongation also support designs with a small folding radius.

“Manufacturers of flexible and foldable devices need an elastic adhesive that is easy to process, cures at low temperatures and can withstand repeated folding and unfolding,” said Jayden Cho, global marketing segment leader for Consumer Electronics at Dow. “This breakthrough Dow adhesive speeds production with primerless adhesion, cures efficiently with mild heat and has the right modulus for an elastic layer within a foldable display. The new adhesive also supports the reliability of consumer devices by withstanding the demands of greater use.”

DOWSIL VE-8001 Flexible Silicone Adhesive can be applied with screen printing, roll-to-roll coating, automatic dispensing or injection molding. The adhesive’s viscosity makes it easy to apply to substrates such as the etched areas of thin stainless-steel sheets used as frames underneath the display of foldable laptops. DOWSIL VE-8001 Flexible Silicone Adhesive supports low temperature curing (80°C for 1 hour at 300 µm thickness) and higher heat can be applied for accelerated curing. With a working time of 12 hours at room temperature, the adhesive won’t harden prematurely.

Importantly, the adhesive exhibits stable mechanical properties after both dynamic and static testing. Hardness, adhesive strength and tensile strength remain remarkably consistent over time. The elongation is high (40%) and indicates the material’s ability to stretch significantly before breaking. DOWSIL VE-8001 Flexible Silicone Adhesive’s tensile strength and appropriate elongation help to control the stress neutral line preventing damage to the display, especially in its folded area. Along with critical reliability, this innovative adhesive provides shock resistance to help protect the display panel from drops or other impacts.

For more information, visit dow.com/electronics.

Tell Us What You Think!