C2G: NETL’s Low-Cost Coal-to-Graphene Manufacturing Process

Category: Mechanical/Materials

Developers: U.S. Department of Energy, National Energy Technology Laboratory

Co-Developers: Ramaco Carbon

United States

Product Description:Graphene is an amazing new material that is one single atomic layer of carbon that is thick, stronger than steel and possesses a higher electrical and thermal conductivity than copper. Despite these amazing properties, it has not been widely utilized in consumer products because of challenges in producing large volumes of high-quality material affordably. The National Energy Technology Laboratory (NETL)’s Low-Cost Coal-to-Graphene Manufacturing Process uses a molten material as both the catalyst and processing medium in a “one-pot” synthesis that converts lignite, bituminous and anthracite ranks of coal into graphene. It addresses cost challenges by using domestic coal feedstocks which are 15-30 times cheaper than the graphite currently used. The technology also improves costs because it uses simple, inexpensive processing methods with product yields that are 6 to 10 times higher than current approaches using graphite. From a technical standpoint, the invention eliminates unwanted carbon oxidation that often creates material defects and other unwanted characteristics. The carbon product is also of a higher quality than what is commercially available making it a viable candidate to produce materials used in safer cars, better batteries and a host of products used daily.

Developers: U.S. Department of Energy, National Energy Technology Laboratory

Co-Developers: Ramaco Carbon

United States

Product Description:Graphene is an amazing new material that is one single atomic layer of carbon that is thick, stronger than steel and possesses a higher electrical and thermal conductivity than copper. Despite these amazing properties, it has not been widely utilized in consumer products because of challenges in producing large volumes of high-quality material affordably. The National Energy Technology Laboratory (NETL)’s Low-Cost Coal-to-Graphene Manufacturing Process uses a molten material as both the catalyst and processing medium in a “one-pot” synthesis that converts lignite, bituminous and anthracite ranks of coal into graphene. It addresses cost challenges by using domestic coal feedstocks which are 15-30 times cheaper than the graphite currently used. The technology also improves costs because it uses simple, inexpensive processing methods with product yields that are 6 to 10 times higher than current approaches using graphite. From a technical standpoint, the invention eliminates unwanted carbon oxidation that often creates material defects and other unwanted characteristics. The carbon product is also of a higher quality than what is commercially available making it a viable candidate to produce materials used in safer cars, better batteries and a host of products used daily.

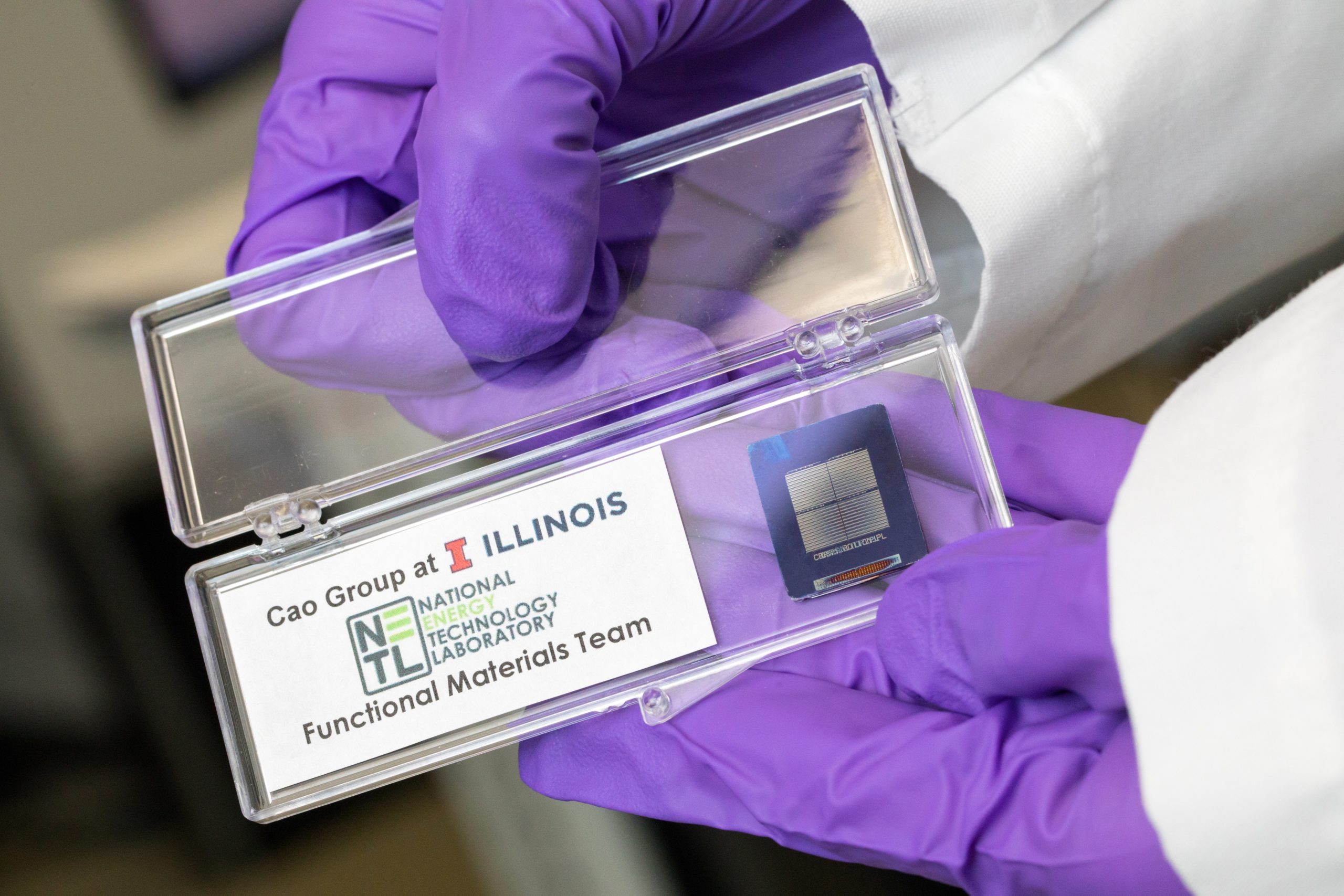

A memristor computer memory device that is enabled by a coal-derived graphene material manufactured at NETL.