Shear Assisted Processing and Extrusion, ShAPE™

Category: Process/Prototyping

Developers: Pacific Northwest National Laboratory

United States

Product Description:ShAPE (Shear Assisted Processing and Extrusion), from Pacific Northwest National Laboratory, is a revolutionary new manufacturing process for a new generation of high-performance materials. Because ShAPE is radically different from conventional extrusion methods — eliminating the need for heating and melting to alloy and form metal products — it offers a scalable pathway to entirely new metals, with a combination of performance characteristics never before reported. ShAPE is also a greener manufacturing process, consuming less energy and emitting fewer greenhouse gases than conventional extrusion of equivalent products. And the benefits of ShAPE are not limited to new metal alloys: conventional metal products also show markedly improved performance and reduced environmental footprint when extruded by ShAPE. Because it is a truly innovative approach to manufacturing, metals producers and end users from industries spanning the breadth of the automotive, aerospace and energy sectors, have joined forces with PNNL to understand how ShAPE can deliver solutions for their specific product needs. The results prove again and again that ShAPE is better, cheaper and greener.

Developers: Pacific Northwest National Laboratory

United States

Product Description:ShAPE (Shear Assisted Processing and Extrusion), from Pacific Northwest National Laboratory, is a revolutionary new manufacturing process for a new generation of high-performance materials. Because ShAPE is radically different from conventional extrusion methods — eliminating the need for heating and melting to alloy and form metal products — it offers a scalable pathway to entirely new metals, with a combination of performance characteristics never before reported. ShAPE is also a greener manufacturing process, consuming less energy and emitting fewer greenhouse gases than conventional extrusion of equivalent products. And the benefits of ShAPE are not limited to new metal alloys: conventional metal products also show markedly improved performance and reduced environmental footprint when extruded by ShAPE. Because it is a truly innovative approach to manufacturing, metals producers and end users from industries spanning the breadth of the automotive, aerospace and energy sectors, have joined forces with PNNL to understand how ShAPE can deliver solutions for their specific product needs. The results prove again and again that ShAPE is better, cheaper and greener.

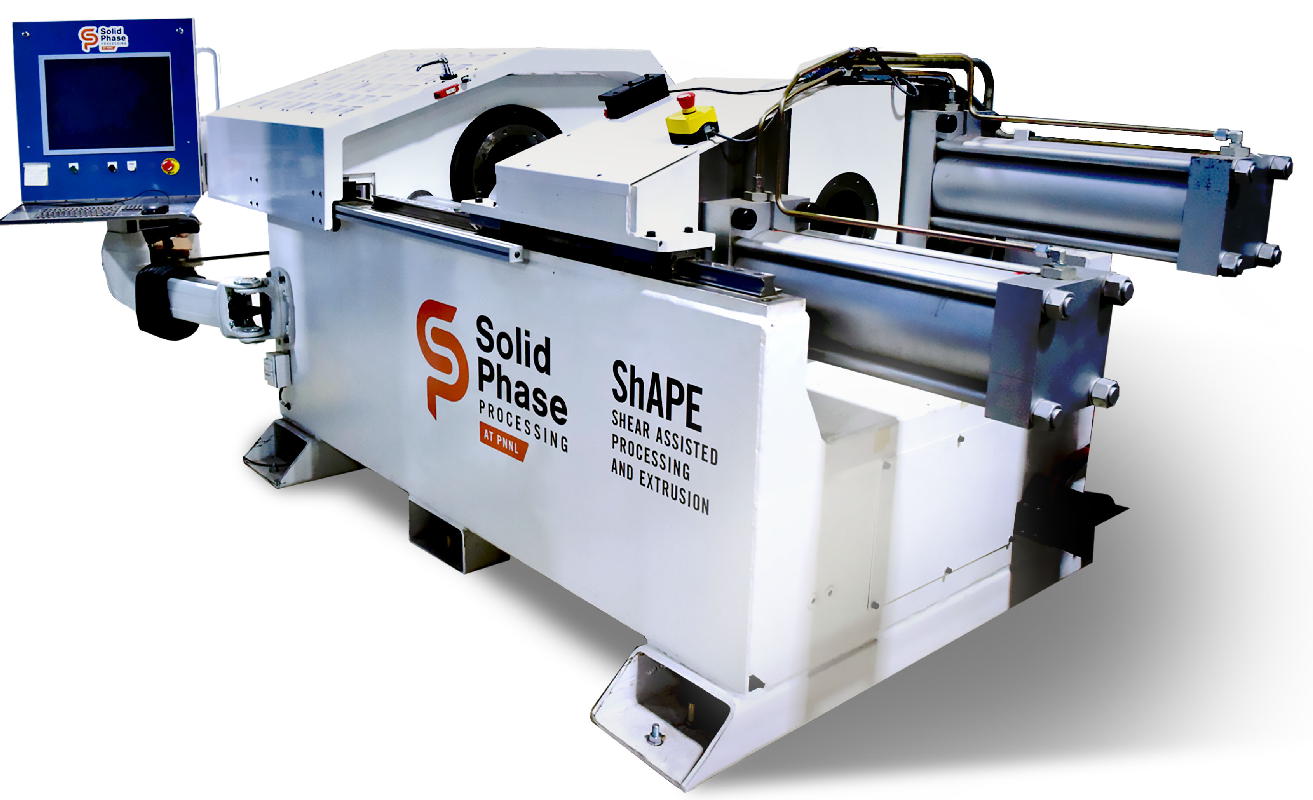

PNNL’s custom-designed ShAPE™ machine is the first of its kind in the world.