A team of researchers led by North Carolina State Univ. has developed a technique that provides real-time images of how magnesium changes at the atomic scale when exposed to radiation. The technique may give researchers new insights into how radiation weakens the integrity of radiation-tolerant materials, such as those used in space exploration and in nuclear energy technologies.

A team of researchers led by North Carolina State Univ. has developed a technique that provides real-time images of how magnesium changes at the atomic scale when exposed to radiation. The technique may give researchers new insights into how radiation weakens the integrity of radiation-tolerant materials, such as those used in space exploration and in nuclear energy technologies.

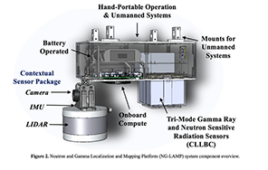

“We used high-resolution transmission electron microscopy (HRTEM) to simultaneously irradiate the magnesium and collect images of the material at the atomic scale,” says Weizong Xu, a graduate student at NC State and lead author of a paper describing the work. “It is a new way to use an existing technology, and it allowed us to see voids forming and expanding in the material.

“Prior to this, we knew radiation could cause voids that weaken the material, but we didn’t know how the voids formed,” Xu says. Voids are physical gaps in materials that begin at the atomic level and can cause a material to swell or crack.

The researchers looked at magnesium for two reasons. First, magnesium’s atoms arrange themselves into tightly packed layers in a hexagonal structure.

“This is important, because many radiation-tolerant materials have the same structure—including zirconium, which is widely used in research on radiation-tolerant materials such as those used in nuclear power plants,” says Suveen Mathaudhu, a co-author of the paper and adjunct asst. prof. of materials science and engineering at NC State under the U.S. Army Research Office’s Staff Research Program.

The second reason they chose magnesium is because it takes less energy to cause void formation in magnesium than in other materials with similar structures, such as zirconium. This lower energy threshold is what allowed researchers to use HRTEM to trigger void formation and capture atomic-scale images of the process with the same microscopy beam.

“You couldn’t use this technique on zirconium, for example,” Mathaudhu says. “But what we’re learning about void formation gives us insight into how radiation damages these kinds of materials.

“In addition to any energy applications, we need to develop new radiation-tolerant materials if we want to explore deep space,” Mathaudhu says. “This may move us one step closer to that goal.”

“If we can improve our understanding of the mechanisms behind void formation, we can begin developing materials to control the problem,” says Yuntian Zhu, a prof. of materials science and engineering at NC State and senior author of the paper.

The paper was published online in Nature Communications.

Source: North Carolina State Univ.