|

High-speed cameras aid in temperature measurements.

Traditional forms of temperature measurement, such as thermocouples and spot pyrometers, often don’t offer the resolution or speed required to fully characterize high-speed thermal applications. This article explores the advantages of high-speed thermal measurement with infrared cameras.

Types of thermal infrared cameras

In general, there are two types of thermal infrared cameras in use today. These are high-performance cooled photon-counting cameras and low-cost uncooled microbolometer based cameras.

The majority of thermographic cooled cameras on the market today use a detector made from indium antimonide (InSb). Cooled cameras work by counting the photons of energy in a specific waveband, typically the midwave IR band at around 3 to 5 µm. The photons strike the pixels and are converted into electrons that are stored in an integration capacitor. The pixel is electronically shuttered by opening or shorting the integration capacitor. Typical integration times for -20 to 350 C objects with a FLIR InSb camera range from about 6 msec to 50 µsec depending on the camera model. These short integration times make it possible to “stop motion” and make it possible to accurately measure very fast transients.

|

Uncooled cameras are lower cost, smaller, lighter and have lower power consumption than the aforementioned cooled counterparts. The pixels of an uncooled camera are made from a material whose resistance changes significantly with temperature. The most common materials for this application are vanadium oxide or amorphous silicon. Thermal energy is focused on the pixel and the pixel physically heats up or cools down. The resistance of the pixel varies with temperature and its value can be measured and mapped back to the target temperature via a calibration process. Since the pixels have a finite mass, they have a thermal time constant. Time constants for modern microbolometer-based cameras are generally between 8 to 12 msec. However, this doesn’t mean that the pixel can be read out every 8 to 12 msec and provide an accurate answer. The rule of thumb for a first-order system responding to step input is that it takes five time constants to reach steady state.

Time constants and a thought experiment

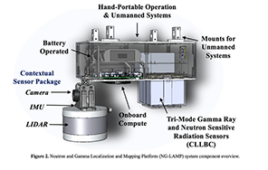

A fun way to think about a microbolometer detector’s time response is to pretend that you have two buckets of water. One bucket is full of well-stirred ice water at 0 C and the other is at a rapid boil at 100 C. Allow the microbolometer to stare at the ice water and then instantaneously switch to the boiling water (a 100 C step input) and plot the resulting temperature. If we covert the thermal time constant of 10 msec into a half time to make for easier math, we get something around 7 msec (Figure 1).

Here the microbolometer reports 50 C at 7 msec or one half time, 75 C at two half times and 87.5 C at three half times. What would happen if users tried to read out this microbolometer at the equivalent of 100 fps or 10 ms? The camera would report back 63 C and have an error of 37 C. The camera would accurately report the temperature of the pixel, but the pixel wouldn’t have reached the temperature of the scene that it was looking. In general, it doesn’t make sense to run microbolometers faster than about 30 fps.

|

Real-world data

Let’s take a look at a printing process that’s required to heat a sheet of paper up to 60 C. The paper is coming out of rollers at 50 in/sec and must be uniform in temperature across both the width and length (Figure 2).

Both a cooled photon counting camera and a microbolometer camera were used to capture side-by-side data. The result: The data from the two types of cameras look dramatically different (Figure 3). The data from the microbolometer shows a big, relatively steady bump in temperature along the length. The data from the photon counting camera shows significant variations in temperature over time.

The InSb camera shows that the heated roller assembly cooled down due to contact with the paper over the first revolution. The bang-bang controller sensed the temperature drop and turned the heater controller fully on again in response. As a result, the roller heated up until the set point was reached and then shut off, and the process repeated. This study convinces R&D engineers of two things: a photon counting camera was required for testing the product and a PID control system must be implemented on the heated roller instead of the simple bang-bang controller if the desired design objectives were to be met.