Flexible, low-cost sensor technology leading to safer and improved diagnoses and treatment of brain disorders has been developed by scientists at King Abdullah University of Science and Technology (KAUST).

Mapping the electrical activity of the brain is critical in understanding neurological disorders, such as depression and Alzheimer’s disease. Currently, multielectrode arrays, called Michigan or Utah arrays, are used to monitor brain activity. Made from layers of conductive silicon needles, these rigid devices are inserted through the scalp to monitor the brain’s surface. The needles can cause inflammation of the tissues and so they must be removed within a year.

Muhammad Hussain and Aftab Hussain from the KAUST Integrated Nanotechnology Laboratory and Integrated Disruptive Electronic Applications Laboratory wanted to develop a soft and flexible sensor that could be placed on the surface of the brain within the intracranial space, providing better contact and reducing the risk of damage to tissues.

“Sensors require associated electronics to interface with us, and these electronics dissipate heat causing a burning effect in the brain which can permanently damage tissues,” explains Hussain. “The challenge is to keep the electronics away from the brain.”

Working within these parameters, they fabricated a sensor made from gold electrodes encased in a polymer coating with their connections oriented vertically, and, by placing the connectors on top of the sensor and allowing them to pass through the polymer support, an integrated circuit (IC) could be attached to the flip side of the device, isolating it from the brain surface and preventing hotspots.

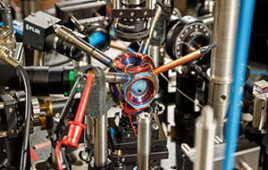

Through Polymer Vias based 3D integration simplifies the path towards high-resolution brain machine interfaces. Image: © 2016 KAUST

The intracranial space of the brain presents an area of only 64 cm2 for mapping more than 80 billion neurons, so not only is it safer to prevent the electronics from making contact with the brain, it also maximizes the number of neurons that can be monitored by the sensor array.

“The sensor is in contact with the soft tissues of the brain, where it collects activity data, and the IC is placed on top, with a soft insulating polymeric material separating them, allowing a larger area to be mapped and a reduction in the heating effect,” says Hussain.

By using state-of-the-art technology, used for fabricating integrated circuits, the researchers have developed a method that could lead to mass-produced sensors that are safer, have improved mapping capabilities, and are also robust enough for long lasting functionality.

“We are currently collaborating with Harvard-MIT Medical Institute on using the technique to improve the efficiency of the mapping interface system,” says Hussain.