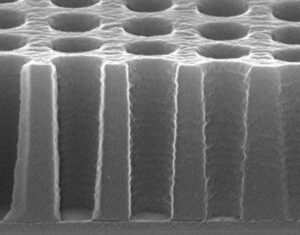

Cross-section SEM image showing 300nm 1:1 contact holes patterned in 1.38µm film thickness on 900Å BARC (Image: Qnity, shown on the UV™ 26GNF KrF Photoresist page)

Qnity’s UV 26GNF photoresist took home a 2025 R&D 100 Award in the Mechanical/Materials category for delivering what the semiconductor industry thought was still years away: a non-fluorine lithography material that actually improves performance. In this interview, Randal King, Qnity’s Chief Technology and Sustainability Officer, explains how a team of about 30 scientists accomplished in under three years what the industry had projected would take five to ten. The key accelerant was data science layered on top of decades of lithography expertise stretching back through DuPont, Dow, Rohm and Haas, and Shipley.

“We get to what we call innovate for good. In other words, come up with a great innovation, but it’s also more sustainable,” King says. With the KrF product now commercially available, Qnity plans to extend its non-fluorine chemistry across the full portfolio, from KrF to ArF to EUV, effectively greening every node in the lithographic lineup.

Tell Us What You Think!

You must be logged in to post a comment.