Scientists from The Hong Kong Research Institute of Textiles and Apparel (HKRITA) have developed a method to turn fruit and beverage waste into a leather-like material and a biocellulose (BC) fiber that can be used for textiles.

Saving the environment

The team was inspired by the environmental effects of traditional cellulose fibers. Cotton, for example, requires a substantial amount of water, the use of pesticides and takes 150 to 180 days to grow. Cotton production also emits an estimated 1.9 kg of carbon dioxide for every kilogram of fiber. Wood-based fibers like viscose require deforestation and toxic chemicals in the process of turning cellulose into fibers, all of which harm the environment.

In comparison, BC fibers grow without pesticides in 14 days and consume less water than cotton. The BC leather is also biodegradable, unlike other leather alternatives, which are usually made from plastic.

Biocellulose spun into fiber for textile production. Credit: HKRITA

The BC leather avoids petroleum-based raw materials that are used to make synthetic leathers. It also eliminates the need for rearing cattle, which accounts for 68% of the leather industry’s emissions per year. The Leather Working Group found that 1 square meter of finished leather emits approximately 22.48 kg of carbon dioxide.

Producing material from waste

BC is a high-purity material with a high degree of polymerization and strength, meaning it can be processed into fibers without extensive chemical processing. The material is strong, flexible and stretchy, making it ideal for making clothes, HKRITA said.

BC is produced by a symbiotic colony of bacteria and yeast. During the fermentation process of kombucha, a film of BC is produced. It can also be produced from beverage and fruit waste. The researchers found a way to take this film, usually waste, and recycle it into fiber and a leather-like material.

The project began in 2022, and the team was able to produce a garment made from BC fibers in one year. After that, they turned to making the BC leather alternative. The BC leather can now be used to make accessories such as purses and watch straps.

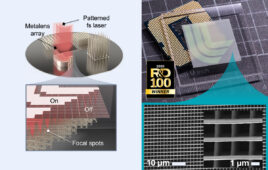

Leather-like film made from BC. Credit: HKRITA

“In the long run, this project has the potential to open new possibilities for eco-friendly fashion, offering sustainable alternatives to both traditional textiles and synthetic materials,” said a spokesperson.

HKRITA partnered with local beverage and food companies, which provided the food waste used in their experiments. The repurposing process has the potential to become a closed-loop recycling process. Food waste is provided from restaurants, turned into garments and accessories, which biodegrade into the soil where food is produced or livestock graze, beginning the cycle again.

The technology is patented in the U.S., Hong Kong and Japan. The researchers are planning to continue refining the process to make it more cost-effective and scalable.