International Freezer Challenge honors Univ. of Illinois

with 2021 “Winning Streak Award.”

By Becky Chambers Hennessy, contributing writer

(This is part two of a two-part series. Read part one, Facing sustainability in the lab, here.)

The University of Illinois Urbana-Champaign is continuing a hot streak in arguably the coolest competition around. The university was recognized for a fourth straight year after earning first place in the Academic Category for reducing the environmental impact of its cold storage practices in its facilities.

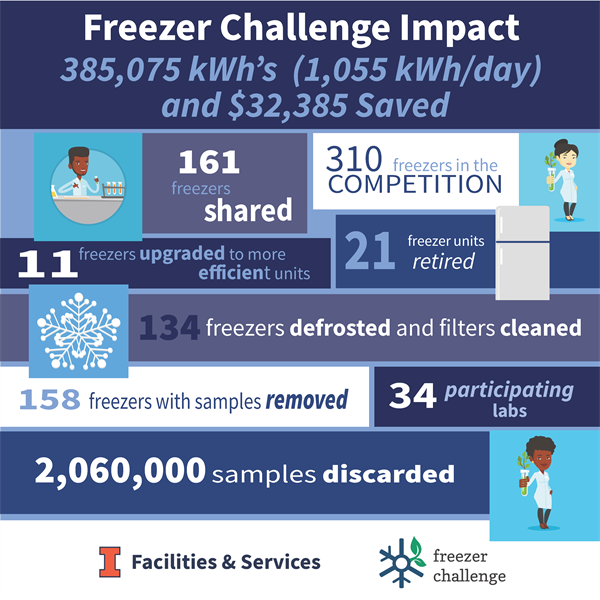

This year, U of I’s 34 labs and 310 freezer units combined saved about 385,000 kilowatt-hours (kWh), or the equivalent of 35 typical U.S. homes, as a part of the International Laboratory Freezer Challenge co-sponsored by My Green Lab and the International Institute for Sustainable Laboratories (I2SL). The amount is a new campus record and resulted in a utility cost savings of $32,385.

R&D World caught up with U of I science community members to ask about efforts that led to the prestigious award: Research Associate Deborah S. Katz-Downie of the Downie Lab, School of Integrative Biology; Professor Martin Gruebele of the Gruebele Lab, affiliated with the Departments of Chemistry, Physics, the Center for Biophysics and Computational Biology, and the Beckman Institute; and Paul Foote, Energy Efficiency and Conservation Specialist.

Did incorporating sustainability in cold storage management interfere with your science research?

Deborah S. Katz-Downie: Incorporating sustainability in cold storage management did not interfere; in fact, it helped us to organize and improve our attention to detail when it comes to all lab members tracking samples throughout all lab protocols. Lab managers therefore spent less time trying to figure out who owned what in the freezers and whether they were still needed.

Martin Gruebele: No. While reorganizing storage did require some time, we also were able to eliminate samples that were no longer needed and organize inventory better to speed up locating items. In addition, we coupled most of the reorganization with a lab renovation. The renovation made access to some equipment impossible but allowed group members’ time to be gainfully spent on organizational tasks.

What key cold-storage management practices did you employ?

Paul Foote: Top action items achieved during this year’s competition include retiring 21 freezer units of the 310 that were part of the competition. We also upgraded 11 freezers to more efficient units, including 161 that are shared with other labs. Not least, we were able to discard more than two million samples.

I should emphasize that our researchers’ familiarity with the challenge’s best practices, combined with impacts of the pandemic, generated opportunities to evaluate sample management. Discarding millions of samples made it easy to retire freezer units. Twenty-one units is the largest quantity retired to date.

In what ways did you go beyond standard cold storage practices?

Martin Gruebele: We reorganized our storage in two freezers so that one holds older, less frequently accessed samples in high density, while the other allows for faster access.

What cost and other benefits did you realize in participating in the freezer challenge?

Paul Foote: Utility cost avoidance is a tremendous benefit. In addition, lab operations are streamlined and have become more efficient, organized, and sustainable. When the pandemic hit, our labs simply had to recall actions from the past year and list them on the score sheet, thus giving them a leg up in the competition.

What can freezer challenge participants working in labs outside of academia learn from your program?

Paul Foote: Lab managers say participating in the freezer challenge helped their operations by prioritizing cold-storage best practices in lab operations. Efficiency gains, sample management techniques and energy-saving advantages become a permanent part of lab procedures. Many of our principal investigators are thankful they implemented these strategies and best practices due to these ongoing benefits.

How will you improve best practices in preparation for the 2022 International Freezer Challenge?

Deborah S. Katz-Downie: We will improve our best practices in preparation for the 2022 challenge by training new lab personnel in freezer storage protocols. This will ensure a smooth transition to documenting our 2022 freezer challenge efforts.

Paul Foote: For one, we’ll continue our focus on temperature-tuning because the benefits are terrific: Energy savings, increased equipment lifecycle, along with sample safety and integrity to name a few. We recognize the advantages of adjusting freezer set points to warmer settings. So, temperature-tuning will be a key focal point in the 2022 competition.

Overall, our primary focus will continue to be on promoting the program and securing the commitment of more labs to participate. Our Facilities & Services division through various initiatives has continued to emphasize that conserving energy is everyone’s responsibility on campus and a part of a larger team effort.

Getting more people to take action is important both to the freezer challenge and to reaching our campus goals of achieving carbon neutrality as soon as possible. Every researcher can make a difference.

A look at the 2021 Freezer Challenge

Participants in this year’s International Laboratory Freezer Challenge, co-sponsored by My Green Lab and the International Institute for Sustainable Laboratories (I2SL), achieved a combined energy savings of 4.3 million kilowatt hours per year — up from 3.2 million kWh per year in 2020’s competition. Savings are equivalent to reducing carbon emissions by 3,000 metric tons per year.

After having earned the top Academic Organization award for the fourth straight year, the University of Illinois Urbana-Champaign took home the 2021 Winning Streak Award. (See sidebar.)

By organization:

- Academic — University of Alabama Birmingham

- Biotech/Biopharma — AstraZeneca

- Government — The National Institutes of Health

- Hospital/Clinical — Children’s Hospital at Westmead, Australia

“Honorable mentions for organizations go to Merck (known as MSD outside the United States), the University of Southern Denmark, and the Royal College of Pathologists of Australasia, all of whom gave the competition their all, achieving some incredible energy savings in the process.”

Starting in 2021, the challenge began awarding labs by research sector, recognizing small, medium and large labs — determined by number of members — as well as biorepository labs:

By research sector:

- Research Materials Management Lab in Discovery Technologies at Amgen Thousand Oaks, California

- Bioscience Lab at Domainex, Saffron Walden, United Kingdom

- Immunology Biology Lab, Janssen Pharmaceuticals, La Jolla, California

- Endocrinology Laboratory at Children’s Hospital at Westmead, NSW, Australia

- Hemostasis Reference Laboratory, Hamilton, Ontario, Canada

- MTS Cryo Stores UK Limited, Nottingham, United Kingdom

- Health Microbiology Laboratory, Research Center for Biology, Indonesian Institute of Sciences, Indonesia

- The Laboratory of Cell Biology of the National Cancer Institute at the National Institutes of Health, Bethesda, Maryland

- Immunoassay Biomarker Core Laboratory, School of Medicine, University of Dundee, Australia

- Van Der Pol Lab at the University of Alabama at Birmingham

- Lab + Teaching Lab (Bethan Grist) at Coventry University, United Kingdom

- BioSpecimen Processing Facility at the University of North Carolina at Chapel Hill

Credit: My Green Lab and International Institute for Sustainable Laboratories

Tell Us What You Think!