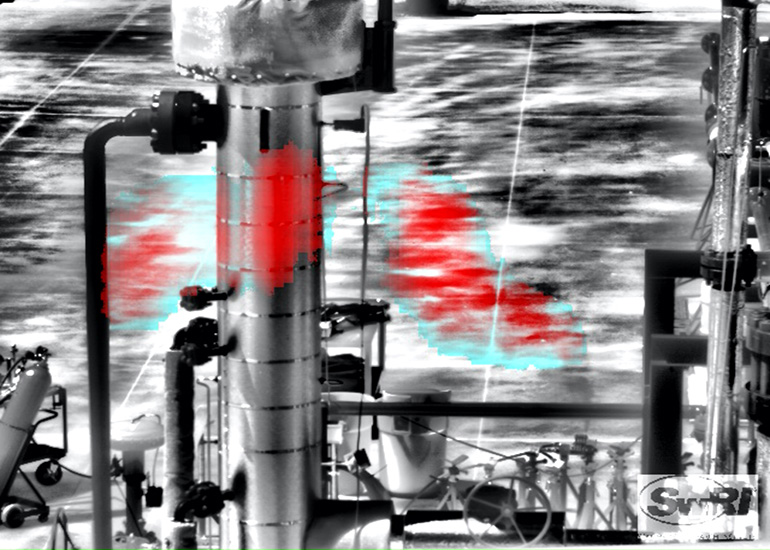

A methane plume (red and blue) was captured with a longwave infrared thermal imager. SwRI will quantify fugitive methane flow rates using machine learning, thermal imaging and lidar technology.

Southwest Research Institute is developing machine learning algorithms to measure fugitive methane emissions through a project funded by the U.S. Department of Energy through the Office of Fossil Energy and managed at the National Energy Technology Laboratory (NETL).

The project leverages an SwRI technology previously funded by DOE, Smart Methane Leak Detection, or SLED/M — a computer vision system that accurately detects small methane leaks that typically go unnoticed along natural gas pipelines and in compressor stations.

Over the next year, SwRI will enhance algorithms to quantify leaks using a low-cost longwave infrared thermal imager and a lightweight lidar (light detection and ranging) system. Natural gas leaks are typically measured from a single point using a diode laser absorption spectroscopy instrument, which must be moved to several positions to gather data.

“Conventional methods can be costly and time-consuming, and they often fail to pinpoint leak sources,” said Heath Spidle, a research engineer leading the project for SwRI. “This new technology will enhance SLED/M’s proven methane detection algorithms with a physics model using 3D visuals to measure the volume of fugitive methane emissions.”

The DOE is particularly interested in developing new scalable quantification technologies, partly in response to a recent Stanford study that found only one in nine methane detection technologies are reliable.

“This newly added task will continue the important research being done at SwRI,” said Joe Renk, the DOE NETL senior federal project manager overseeing the work. “The use of gas imagers and lidar with machine learning presents an opportunity to develop cost-effective solutions to accurately quantify natural gas flow rates.”

SwRI’s Critical Systems Department will develop algorithms and integrate sensors with computational fluid dynamics, with support from the Institute’s Fluids Engineering Department.

“Having computer scientists who can work in-house with sensing experts and fluids engineers is a major advantage in developing a quantification solution with machine learning technology,” added Dr. Steve Dellenback, vice president of SwRI’s Intelligent Systems Division.

Fusing computer vision and machine learning, SwRI’s SLED technology has been adapted to autonomously detect methane, liquid hazardous leaks and even crude oil on water surfaces. SwRI is working with government and industry to apply smart leak detection algorithms on aerial drones, aircraft and stationary devices.

Conventional methane detection systems, designed to locate larger leaks, suffer from false positives and missed detections, which hamper effectiveness and utilization by industry. SLED/M substantially reduces false positives by optimizing algorithms to reliably detect smaller leaks under a variety of conditions.

SwRI is a leader in the development of machine learning and computer vision solutions that help government and industry advance science and technology from deep sea to deep space.

For more information, visit methane.swri.org

Tell Us What You Think!