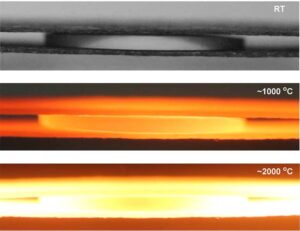

The research team from University of Maryland College Park and HighT-Tech has invented and patented an ultrafast high-temperature sintering (UHS) process that can achieve record-high temperatures of up to 3,000° C and ultrafast heating rates of up to 100,000° C/minute via radiative heating. The UHS method can directly sinter oxide precursors into solid, dense ceramics in just seconds, more than 100–1000 times faster than traditional sintering.

The research team from University of Maryland College Park and HighT-Tech has invented and patented an ultrafast high-temperature sintering (UHS) process that can achieve record-high temperatures of up to 3,000° C and ultrafast heating rates of up to 100,000° C/minute via radiative heating. The UHS method can directly sinter oxide precursors into solid, dense ceramics in just seconds, more than 100–1000 times faster than traditional sintering.

Ceramics are widely used in electronics, energy storage and extreme environments due to their high thermal, mechanical, and chemical stability. The sintering technology of ceramics can be traced back to more than 26,000 years ago. However, the rapid development of modern technologies demands innovation in this ancient field, particularly the need for high-throughput and energy-saving ceramic sintering methods.

This technology was initially reported in Science and further developed as a product in 2020. It has raised significant interest from industry and government agencies. This ultrafast sintering technology can be used for a wide range of fields, including batteries, fuel cells, as well as metal and glass production.

Tell Us What You Think!