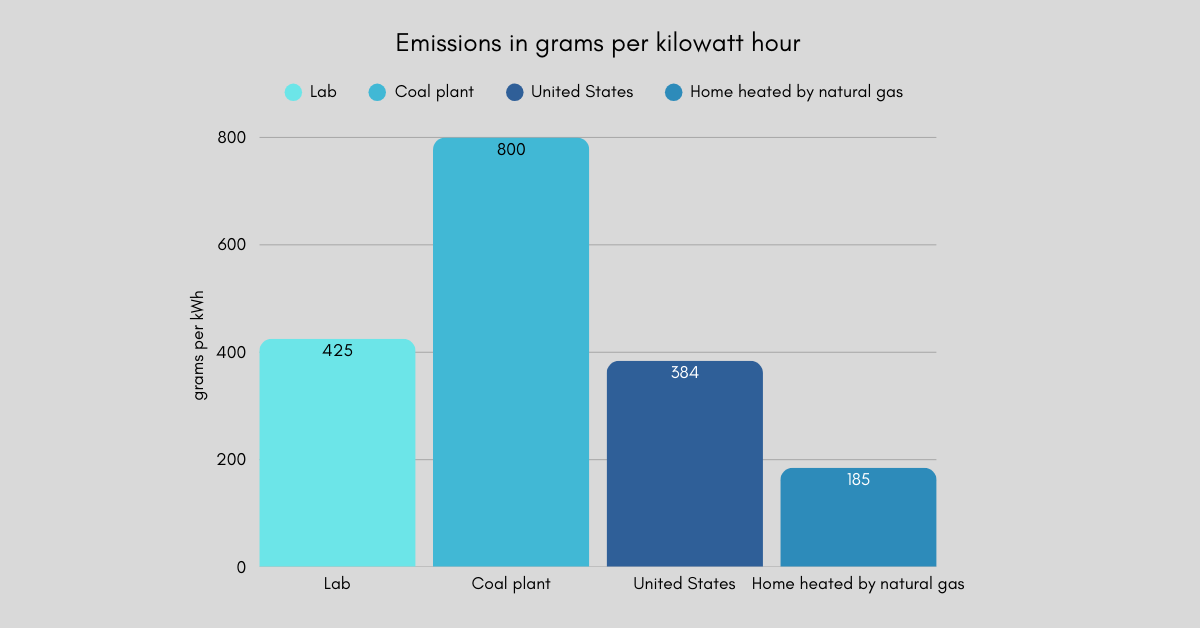

On average, laboratories emit 425 grams of carbon dioxide per kilowatt-hour of electricity produced, more than half the emissions of a coal plant.

Fume hoods account for a significant part of a lab’s energy consumption. Hoods run continuously, exhausting the air in the fume cupboard and forcing the HVAC system to work harder to replace it. A fume hood running continuously can use as much energy as 3.5 homes per year.

Shut the sash

The easiest way to reduce the energy consumption of a fume hood is to ensure that the sash, the movable pane in front of the hood, is always in the lowest position. This reduces the amount of air that is exhausted, allowing the fan to operate at a lower speed and reducing the load on the heating and cooling system.

Even when a fume hood sash is completely closed, there is still some air flow allowing for continuous ventilation. This means it is safe to close the sash when a fume hood is not being used. Keeping the sashes closed when not in use also reduces the chance of injury from unintended reactions or spills.

Harvard University started a shut the sash campaign in 2005, reporting that it saved more energy than any other behavior program at Harvard to date. According to Jerome Connors, the associate director of Harvard’s Department of Chemistry and Chemical Biology, the program saved approximately $200,000 to $250,000 and decreased energy consumption by 70%.

In addition to closing the sash, labs looking to save energy can switch to a variable air volume (VAV) system, which reduces the volume of air taken from the fume cupboard when the sash is closed. TEL claims VAV controllers can reduce energy costs by up to 85%. The University of Reading updated 44 hoods to VAV systems, saving £223,958 ($295,848) per year in energy costs.

Labs can also invest in automatic sash operators, which can open and close the sash automatically, eliminating the need for scientists to remember to close the sash. The operators close the sash when the user walks away from the fume hood after a customizable delay. Mott Manufacturing estimates that an automatic fume hood operator could save labs up to $6,780 annually.

Labs can also set fume hoods to a lower face velocity. Face velocity is the speed the air enters the open sash area, usually measured in feet per minute (FPM). Traditionally, the rule of thumb has been a face velocity of 100 FPM. However, higher-performance fume hoods can be run at 60 FPM, saving energy by reducing the total exhausted air.

Tell Us What You Think!

You must be logged in to post a comment.