by Jim McMahon

Astronomers have confirmed more than 5,000 exoplanets orbiting distant stars. There are a few aspects that are needed to characterize an exoplanet. One is the size of the planet, and the other is the mass of the planet.

Space-based missions, such as the Transiting Exoplanet Survey Satellite (TESS) launched in 2018, find exoplanets through events called transits, where a planet periodically blocks part of the light from its host star. These space-based missions do the precision photometry that is used to derive both the size of the planet — how big it is physically, the planet’s diameter — and how far away from the star it is. TESS finds the most promising exoplanets orbiting our nearest and brightest stars, Earth-sized and super-Earth-sized exoplanets which are no larger than twice the size of Earth.

Once space-based observations of an exoplanet are made, follow-up ground-based measurements are needed to characterize the mass of the planet. This is achieved by determining how fast the planet’s star is moving, and its radial velocity, and needs to be performed with extreme precision, which to date has only been demonstrated from a ground-based location. Once measurements of the size and the mass of the planet are known, its density can be determined, which enables an assessment of the planet’s composition — whether it is a gas giant or a small rocky planet, or something in between.

Keck Planet Finder

Ground-based radial velocity (RV) measurements are made from dozens of observatories around the world. Many are located at smaller facilities where routine observation is possible. To reach the precision to characterize earth-like planets, RV measurements need to be made from large telescopes at exquisite observing sites.

Until recently, many ground-based radial velocity measurements were performed with the High-Resolution Echelle Spectrometer (HIRES), located at the W.M. Keck Observatory (WKMO) on the summit of 13,796-ft Mauna Kea in Hawaii. HIRES’s precision measurements can spot stars moving back and forth or wobbling, at a speed of about 200 cm/second.

Moving the KPF into position at the W. M. Keck Observatory in Hawaii. (Courtesy UC Berkeley Space Sciences Laboratory)

But scientists wanted to push the technology further to permit locating even smaller planets that exert a weaker tug on their host stars. A planet’s gravity causes this solar wobbling, very slightly affecting the movement of the star. More massive planets with higher gravity are easier to detect than smaller rocky planets.

This led to the development of the Keck Planet Finder (KPF), a next-generation optical spectrometer, also located at the W. M. Keck Observatory in Hawaii, that saw first light in November 2022. Like HIRES, KPF was designed to discover and characterize extrasolar planets using the radial velocity method, but with much higher precision, capable of detecting stellar motions of only 30 cm/second.

First envisioned in 2014, KPF has been jointly designed and built by the University of California, Berkeley Space Sciences Laboratory (SSL) in Berkeley, California, and the California Institute of Technology in Pasadena, California.

“Since its inception in 1959, SSL has participated in over 50 NASA space science missions, including the Apollo, Mars, Discovery, and Explorer programs, as well as many international space missions,” said Kodi Rider, project manager of Keck Planet Finder at UC Berkeley Space Sciences Lab. “KPF is focused to not only find smaller rocky planets, but ones in the habitable zones of their stars. Its precision enables unprecedented measurements of the masses, orbits, and compositions of smaller planets.”

Thermal stability

Optical components of KPF are positioned on a bench inside a vacuum chamber. (Courtesy UC Berkeley Space Sciences Laboratory)

KPF was designed from the ground up to track the spectral fingerprints of stars to better than one part-per-billion precision. This scale of measurement represents a significant technological challenge and required every layer of the KPF system to be optimized to maximize performance.

A critical aspect of KPF is thermal stability. Inside the instrument, light is reflected between mirrors. If the base of the spectrometer were to expand because of temperature change, then the distance between the mirror would change, resulting in light landing in the wrong place. This may appear that stellar light has Doppler-shifted because of orbiting planets, when in fact, the instrument itself would have shifted.

“To mitigate this potential, a key innovation of KPF is the application of a special kind of ceramic-glass hybrid material called Zerodur, that is used for the base of the instrument and main optical components such as mirrors,” said Rider. “Developed by Schott AG, Zerodur has extremely low-thermal expansion with approximately 1,000x less thermal movement than steel.”

KPF is the first spectrometer to fully integrate Zerodur into its design, and the ceramic-glass hybrid material is fundamental to making KPF the world’s most advanced high-resolution spectrometer for visible wavelengths.

Elimination of vibration

There are other factors beyond thermal stability that needed to be considered when attempting to measure stellar radial velocity at the rate of 30 cm/second. The Zerodur base and optical components of KPF are positioned on a bench inside a vacuum chamber, which is located at the Keck Observatory.

“We became concerned about vibrations when measuring at this level of precision,” said Rider. Such as external vibrations from pumps and machines, and from the Keck mirrors themselves rotating. Our tolerance for mirror motions is less than an angstrom, which for scale is half the width of a hydrogen atom.”

One of the five 800CM-1CV Negative-Stiffness isolators supporting the Keck Planet Finder. (Courtesy UC Berkeley Space Sciences Laboratory)

“After a considerable search, we were able to find only one technology with the capability to completely isolate vibrations at the level required for the KPF spectrometer,” added Rider.

The technology selected was Negative-Stiffness vibration isolation, developed by Minus K Technology – an OEM supplier to leading manufacturers of scanning probe microscopes, micro-hardness testers, and other vibration-sensitive instruments, in addition to providing vibration isolation for many aerospace projects. Minus K Technology provided five 800 CM-1CV isolators modified for vacuum compatibility.

Because there is no air or electricity to worry about, Minus K Technology’s Negative-Stiffness isolators are relatively easy to place directly into vacuum environments. There are no exhaust gasses from air valves that need to be dealt with, and no heat dissipation issues to worry about as the isolators do not generate any heat. To be made vacuum compatible, the isolators omit painted surfaces, and use either bare metals or plated metals compatible with the application needs. Special vacuum-compatible parts and greases are used as well.

Virtually all the isolators that Minus K Technology manufactures can be made vacuum compatible for use directly in a vacuum.

“Throughout 2022, we worked closely with Minus K on the design and set up of the vibration isolators, and how we envisioned using them on the KPF,” said Rider. “Five isolators were needed for positioning inside the vacuum chamber, beneath and supporting the bench holding the Zerodur optics base.”

How negative stiffness works

Negative-Stiffness isolators in position within the KPF. (Courtesy UC Berkeley Space Sciences Laboratory)

Because Negative-Stiffness vibration isolators are compact and do not require electricity or compressed air, they enable sensitive instruments to be located wherever they are needed. There are no motors, pumps, or chambers, and no maintenance because there is nothing to wear out. They operate purely in a passive mechanical mode, making them suitable for the vacuum environment needed for KPF.

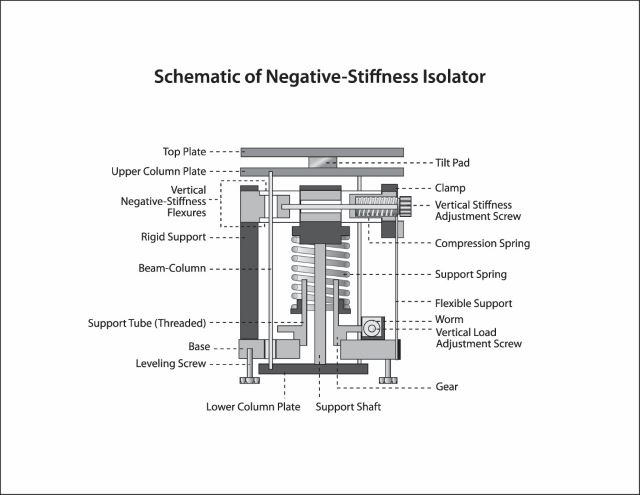

“Vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a Negative-Stiffness mechanism,” said Erik Runge, vice president of Engineering at Minus K. “The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam columns connected in series with the vertical-motion isolator provide horizontal-motion isolation. A beam column behaves as a spring combined with a negative-stiffness mechanism. The result is a compact passive isolator capable of very low vertical and horizontal natural frequencies and high internal structural frequencies.”

What is very advantageous about Negative-Stiffness isolators is that they achieve a high level of isolation in multiple directions. These isolators have the flexibility of custom-tailoring resonant frequencies to 0.5 Hz* vertically and horizontally (with some versions at 1.5 Hz horizontally).

(*Note that for an isolation system with a 0.5 Hz natural frequency, isolation begins at 0.7 Hz and improves with an increase in the vibration frequency. The natural frequency is more commonly used to describe the system performance.)

These isolators deliver very high performance, as measured by a transmissibility curve. Vibration transmissibility is a measure of the vibrations that are transmitted through the isolator relative to the input vibrations. Negative-Stiffness isolators, when adjusted to 0.5 Hz, achieve approximately 93% isolation efficiency at 2 Hz; 99% at 5 Hz; and 99.7% at 10 Hz.

Vibration isolation performance

SSL started building KPF at Berkeley in early 2022, tested the instrument throughout the summer with the Negative-Stiffness isolators, then dismantled it, shipped it to Mauna Kea, and reassembled it for permanent installation on site.

“The Negative-Stiffness isolators were essentially a plug-and-play system,” said Rider. “As soon as we received the isolators we installed them, put the bench on top, set up the vacuum chamber, and started taking measurements. Everything worked as planned.”

“We have been using the Negative-Stiffness isolators for about a year now and the laboratory measurements that we did at Berkeley were about a factor of two better than we were hoping,” added Rider. “Now that we are getting on-sky results with the telescope, we are still at that level with solar radial velocity measurements.”

“KPF has emerged as a powerful tool, both for the discovery and follow-up of planets and for unprecedented insight into stellar behaviors,” explained Rider. “I think Negative-Stiffness vibration isolation has played an important part in the success of KPF.”

For more information, contact Kodi Rider, Project Manager, Keck Planet Finder, UC Berkeley Space Sciences Lab.

For more information on Negative-Stiffness isolators please contact Steve Varma, Minus K Technology, Inc.

Tell Us What You Think!