A rheometer is an instrument which characterizes the flow of a substance in response to forces, its rheology. A viscometer measures a fluid’s resistance to deformation at a given rate. This gives a single parameter, viscosity, for the fluid. Newtonian fluids have a fixed viscosity at a given temperature. As the applied force is increased, their flow rate increases linearly. If the force is plotted against the flow rate, the viscosity is the constant gradient. The rheology of Newtonian fluids can, therefore, be characterized by simply measuring their viscosity at a range of temperatures and plotting this on a graph.

A rheometer is an instrument which characterizes the flow of a substance in response to forces, its rheology. A viscometer measures a fluid’s resistance to deformation at a given rate. This gives a single parameter, viscosity, for the fluid. Newtonian fluids have a fixed viscosity at a given temperature. As the applied force is increased, their flow rate increases linearly. If the force is plotted against the flow rate, the viscosity is the constant gradient. The rheology of Newtonian fluids can, therefore, be characterized by simply measuring their viscosity at a range of temperatures and plotting this on a graph.

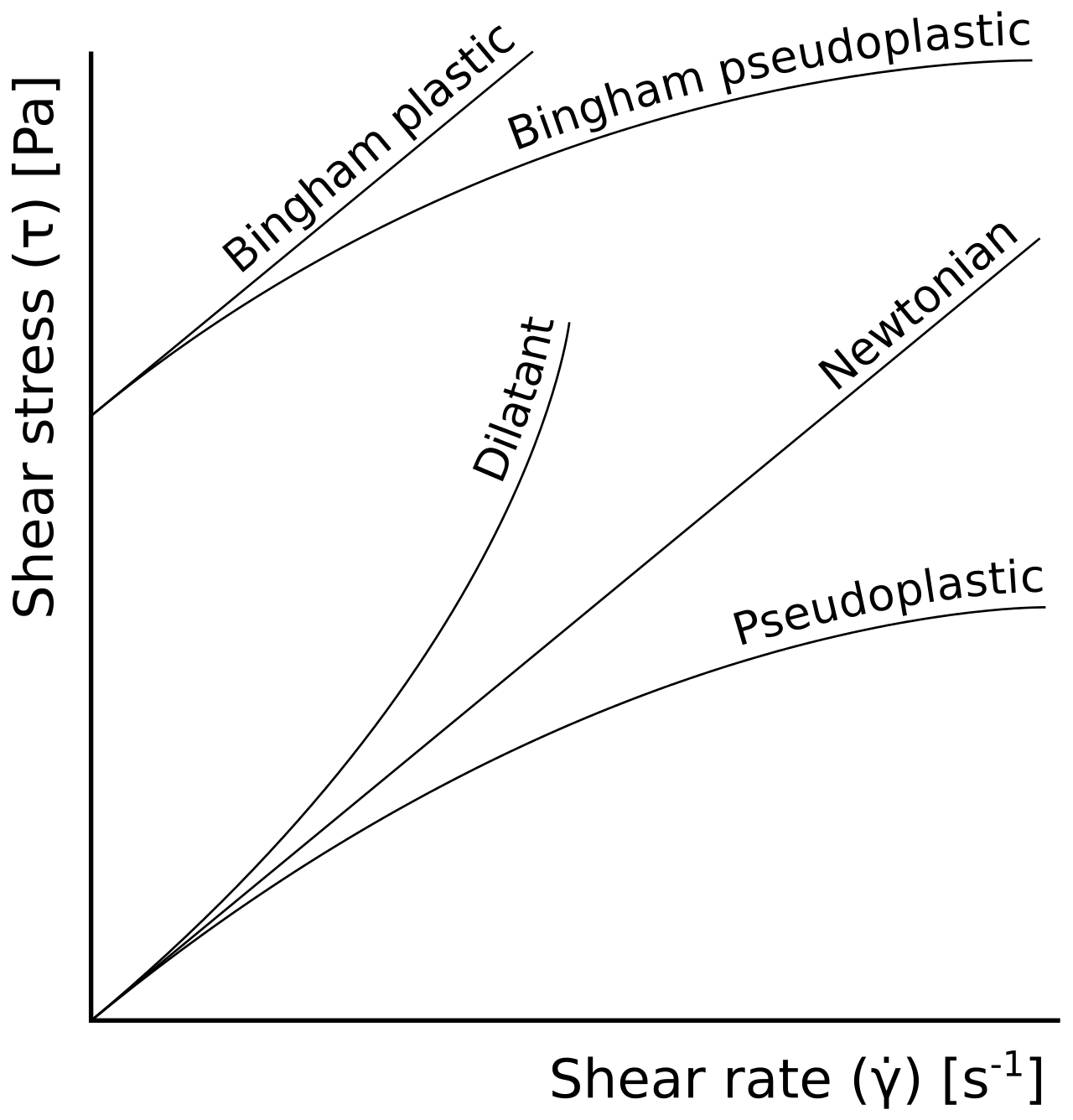

Many substances with complex microstructures behave in a more complex non-Newtonian way, which cannot be defined by a fixed viscosity at each temperature. Examples include sludges, suspensions, slurries and polymers. Types of non-Newtonian behavior are characterized as:

- Non-Newtonian viscosity is used to describe changes in viscosity in direct response to the applied stress.

- Shear thickening, or dilatant, materials increase in viscosity as shear stress increases. A well known example of this is a suspension of corn starch in water.

- Shear thinning, or pseudoplastic, materials reduce in viscosity as shear stress increases. Ketchup behaves in this way explaining why is can be very difficult to pour but then suddenly pours rapidly when shaken.

- Time-dependent viscosity involves changes in viscosity when shear stress is applied over a period of time. When the stress is removed, the fluid’s viscosity does not return immediately but takes a period of time to recover.

- Thixotropic materials become less viscous when subjected to shear stress over a period of time.

- Rheopectic, or anti-thixotropic, materials become more viscous when subjected to shear stress over a period of time. Examples include the synovial fluid which lubricates and protects cartilage in joints

- Viscoelastic materials show a combination of elastic and viscous effects, often behaving like an elastic material when a force is applied over a short period of time, but flowing, or creeping, when force is applied over a longer period of time. Silly putty is an example of obvious viscoelastic behaviour but many polymers exhibit viscoelasticity to some extent.

Rheometers measure these properties by either controlling the applied shear stress (rotational or shear rheometers) or by applying a strain (extensional rheometers). Rotational rheometers are more mature and are commonly used for a wide range of materials.

Tell Us What You Think!